Sheet Metal Forming Simulation

Case Studies

- Multi Step Simulation- Lodent Precision

- Forming Simulation- Corsair F4U

- Forming Troubleshooting- Die Engineering

- Step Optimization- Die Engineering

- Thinning Prevention- Viking Tooling

- ANSYS Simulation- Premier Tool Design

- Forming Troubleshooting- AFC Tool

- First Tryout Success- Minnesota Tool & Die

- Tool Design Testing- Die Enginnering

- Forming Troubleshooting- Malben Engineering

- Forming Troubleshooting- Williams Tooling

- Forming Simulation – Ustun Makina

- Metal Product Development- Rover Australia

Round Peg Fits a Square Hole - Ustun Makina

Round Peg Fits a Square Hole - Ustun Makina

Using the power of simulation technology, even a round peg can fit a square hole for StampingSimulation clients, such as Ustun Makina. Watch the full simulation video.

Ustun Makina (Europe) has been using StampingSimulation services since 2012 to successfully deliver complex sheet metal tooling and stamped products to worldwide OEMs.

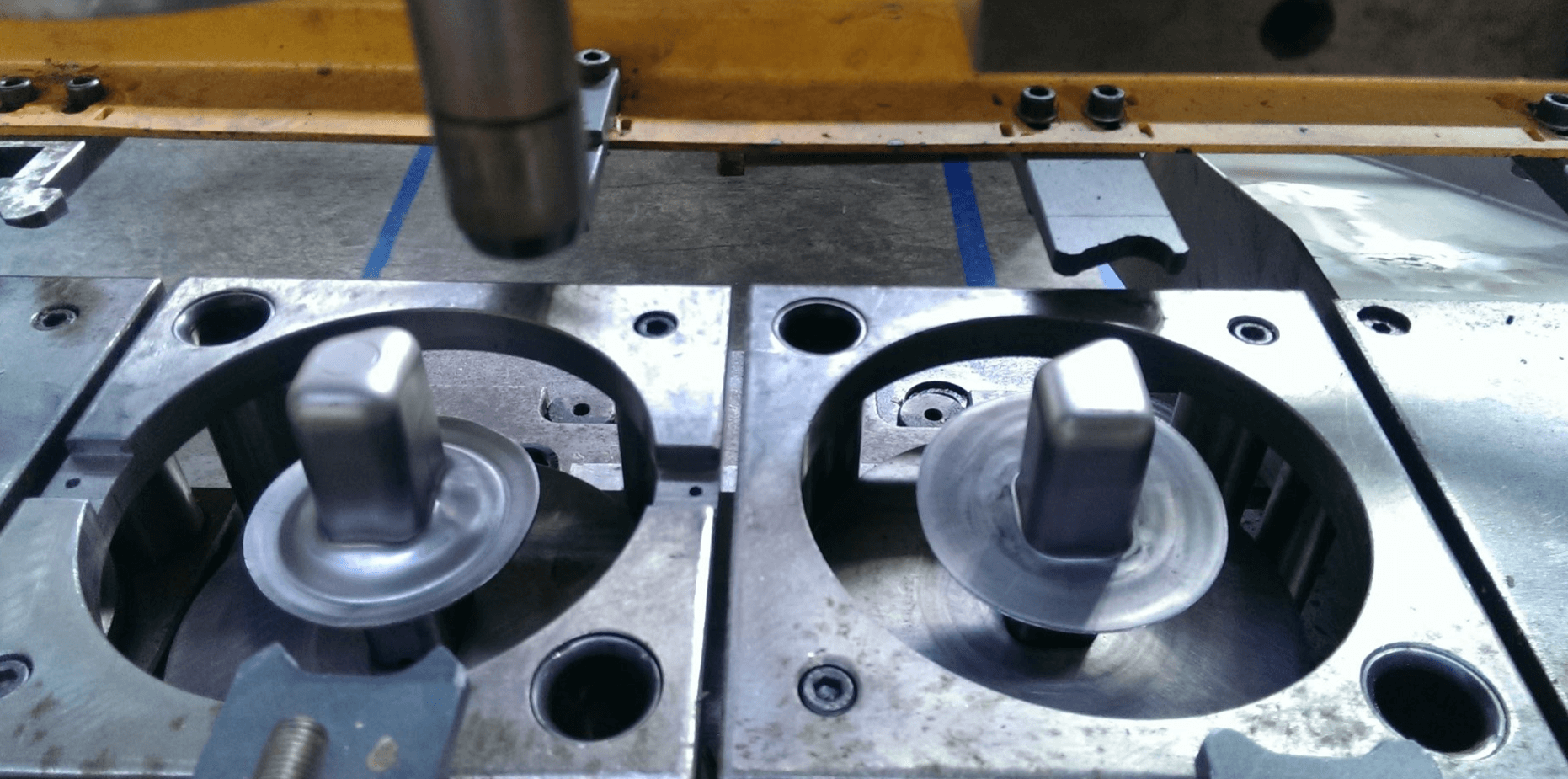

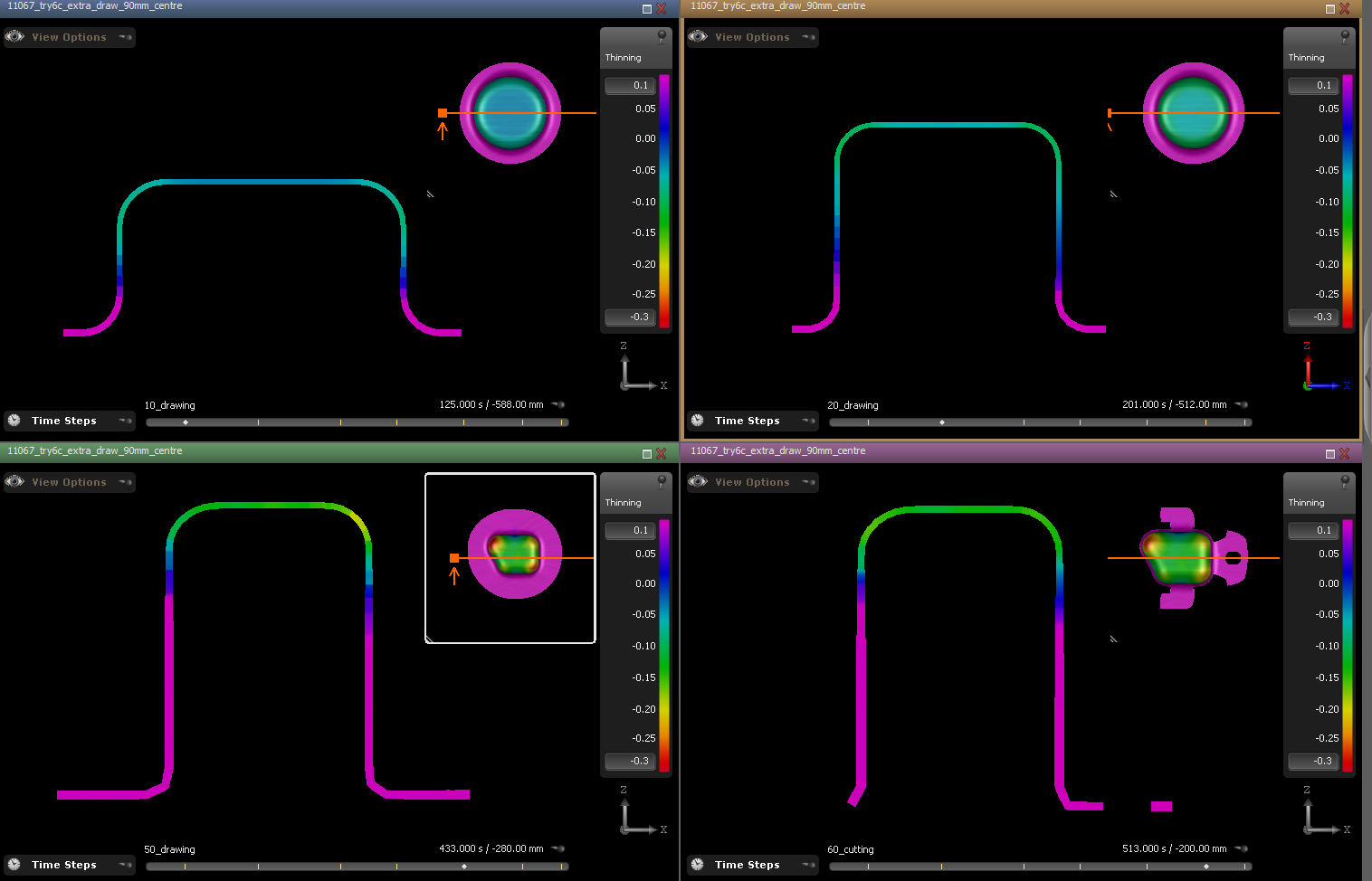

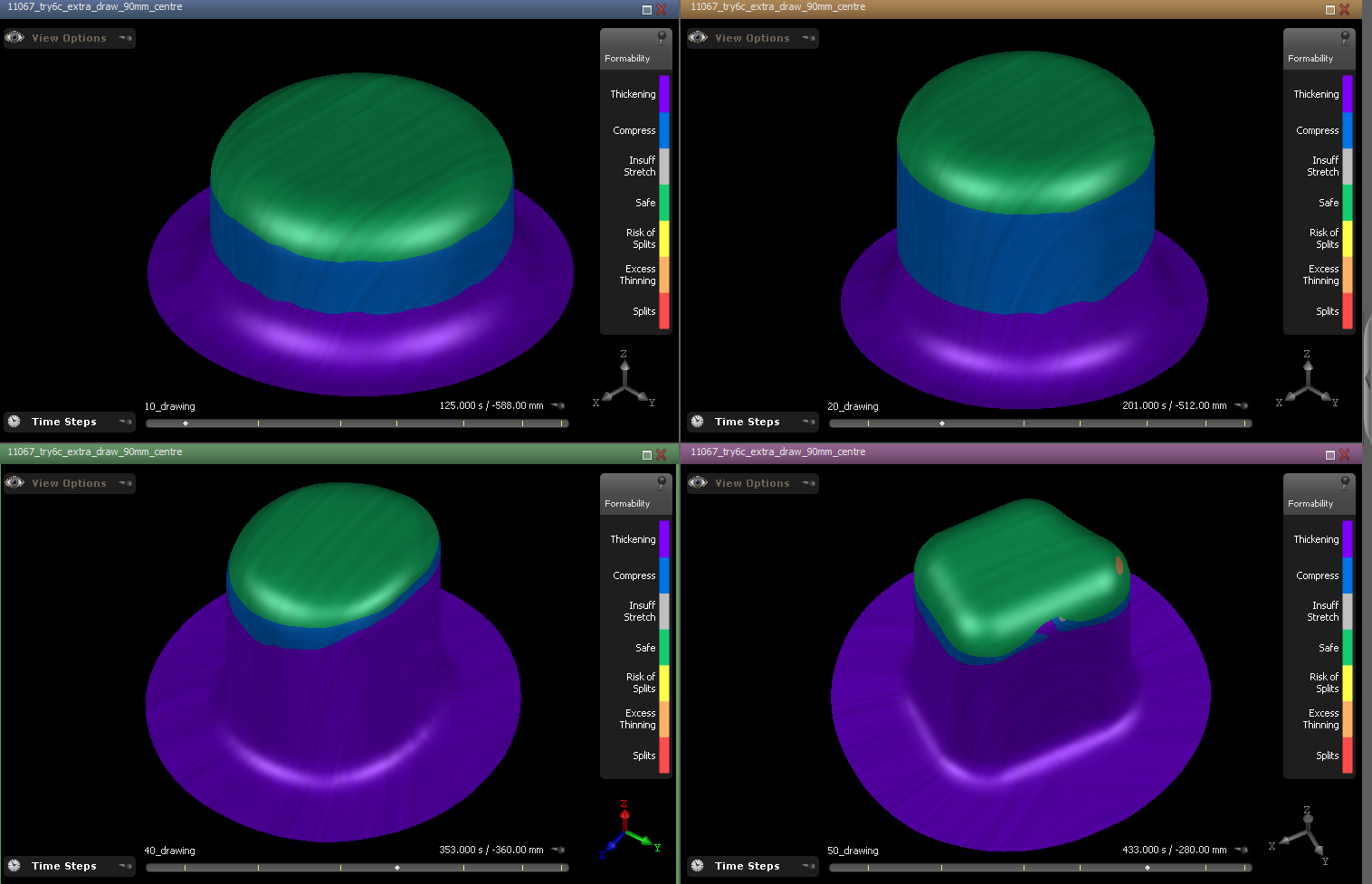

This deep drawn square product shape requires careful design and planning using the full power of AutoForm sheet metal simulation software, to correctly determine how the material can be first drawn up to a deep round shape, then reformed to the final square product.

Careful control of metal thinning/thickening is required to ensure the final square product is not too thin but also does not buckle under compressive stresses during reforming from round to square.

Using the power of simulation, multiple shapes, sizes and process steps can be trialed quickly and efficiently in the virtual world to ensure that all trial and error on the shop floor is eliminated. Toolmaking becomes a once off project task, instead of an unknown cycle of trial and error.

The end result was tooling that was machine onced, and an acceptable part made during first physical tryout (after 35 “virtual” tryouts in less than three days!) with only minor adjustments in the press to get the process running smoothly.

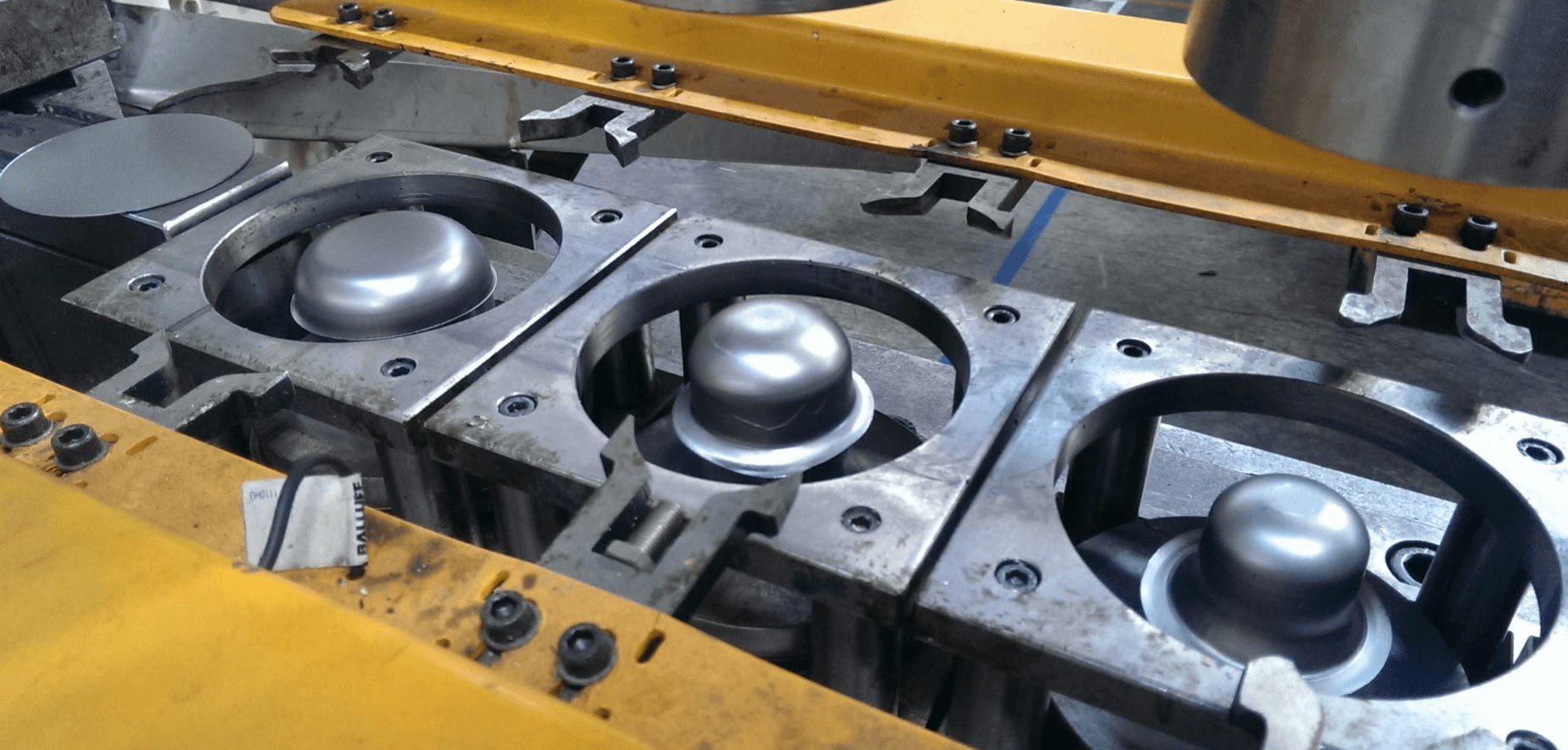

Here's a visual on the progression: