Sheet Metal Forming Simulation

Case Studies

- Multi Step Simulation- Lodent Precision

- Forming Simulation- Corsair F4U

- Forming Troubleshooting- Die Engineering

- Step Optimization- Die Engineering

- Thinning Prevention- Viking Tooling

- ANSYS Simulation- Premier Tool Design

- Forming Troubleshooting- AFC Tool

- First Tryout Success- Minnesota Tool & Die

- Tool Design Testing- Die Enginnering

- Forming Troubleshooting- Malben Engineering

- Forming Troubleshooting- Williams Tooling

- Forming Simulation – Ustun Makina

- Metal Product Development- Rover Australia

Minnesota Tool & Die Case Study

The client required a successful forming process to form the provided 3D Part Geometry. Using our simulation technology, they were able to get great parts at first try out.

Simulation Videos

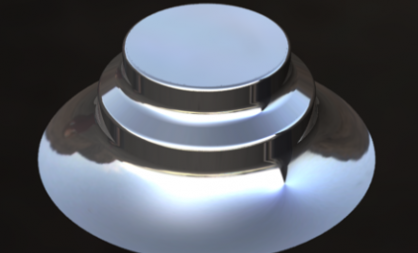

Figure 1: Part Geometry

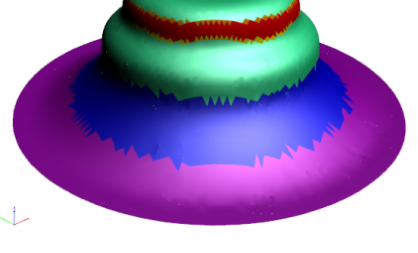

Figure 2: Splits are predicted

Initially, a single stage draw was simulated to determine if the part required more than one forming stage.

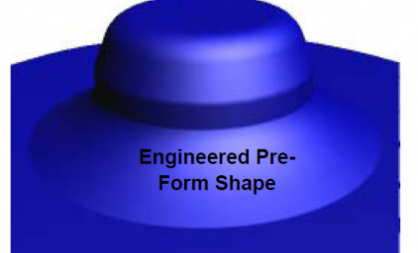

Figure 3: Pre-Form Shape

A pre-form shape was engineered to form the part in TWO stages.

Figure 4: Pre-Form Simulation

The simulation predicted failure to resolve splitting issues in a single stage. We then developed a successful two-stage approach through simulation.

Figure 5: Actual Pre-Form shape is safe!

Figure 6: Simulation predicts a successful part

Figure 7: The Part is formed successfully

The client tooled the process and achieved success at first tryout!