AutoForm Forming R10

While sheet metal forming simulation is a standard feature of AutoForm, users have been asking for the ability to simulate forged and coining processes. Forging is a manufacturing process that involves the shaping of metal using localized compressive forces. It may be performed with a hammer (or stamp) or by using press tools to squeeze the workpiece between dies.

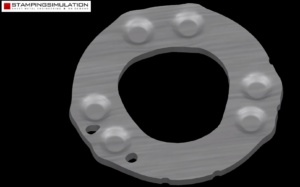

The latest release of AutoForm Forming R10 solves this problem by introducing an element that simulates through thickness changes as imposed by the tool geometry. This means we can now simulate forging and coining processes with R10. For example, if your upper tool has a different offset from your lower tool (click image below for full video), AutoForm Forming R10 will be able to predict correct material behavior based on the actual geometry.

Forged parts are typically used where strength and/or surface finish requirements dictate, such as automotive body panels and structural components for aircrafts. Tensile properties can vary significantly depending on different forging processes, including annealing after forming, so accurate modeling is important during analysis.

StampingSimulation is excited to announce that we’re already using the new element – TS-11 – for “Forged” and “Coined” sheet metal parts. These elements allow you to simulate both forging and coining operations using tools with varying offsets from one another. If this sounds like something you might need in your next project, give us a call or Get a Project Quote now. We can help you simulate any size job.

Other Helpful Reading:

Achieve Metal Stamping Success Through Smart Planning and Production

Understanding The Effects Of Oil Canning in Stamping Simulations