A Simple Sheet Metal Stamping Dies Guide

Contents

What is a Stamping Die?

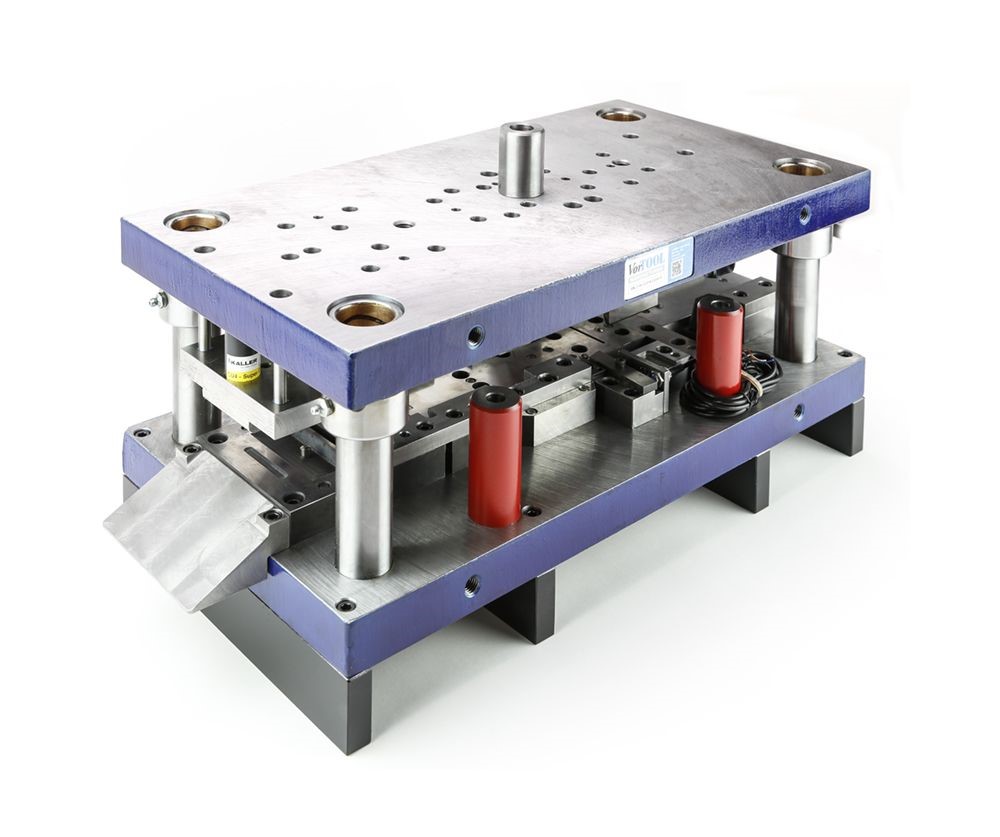

Without reference to any official definition (in our own words!) a stamping die is a hard tool, usually as a male/female pair, that is used to cut, bend, shape or form a sheet of metal into a desired shape. A stamping die is also commonly referred to as a “stamping tool” and often just as “tooling”. Stamping dies are often described as “tooling” because nearly always, more than one stamping die is required to manufacture the required shape, using multiple process steps.

Where are stamping dies commonly used?

The most common application of sheet metal stamping dies, is in the automotive industry. Any automotive component made from sheet metal is generally made in a metal stamping die. Perhaps the second largest application is in house hold consumer goods, such as dish-washers and clothes washing machines. Another industry that commonly use stamping dies is the building industry, although for only a select few sheet metal components, as well as the medical industry. There are many other applications for sheet metal stamping dies but by far when stamping dies are mentioned, automotive is at the forefront of this technology.

What are the disadvantages and advantages of metal stamping dies?

Sheet metal stamping dies are most appropriate when high volumes of parts are required eg: >50,000 parts per year. Correctly designed stamping dies can manufacture sheet metal parts at the rate of 60+ parts per minute, but more commonly at around 20 parts per minute. The disadvantage is that to produce parts at this rate, a large capital investment is required in “tooling”, and cost of such tooling can be in the order of USD $100,000 to $500,000 typically. In addition, this assumes that a line of presses (press machines) is available to run the tooling.

What are the types of stamping dies?

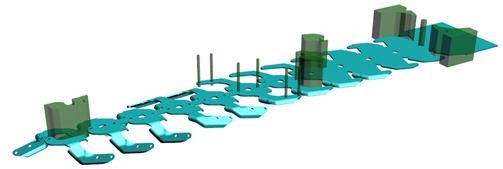

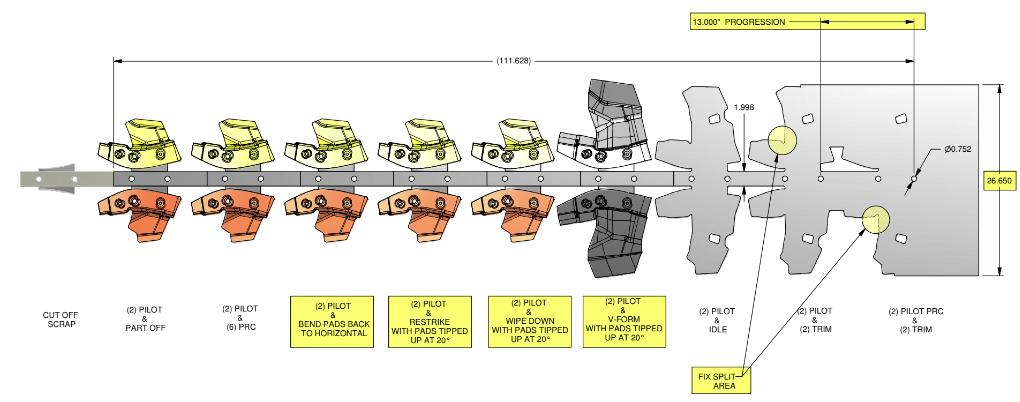

The types of stamping dies are usually categorized by the rate at which parts can be manufactured. For example “pick and place” tooling is a set of stamping dies that require manual labour (by hand) to move the part from tool to tool. Where as “transfer” tooling, usually means the set of stamping dies are linked via a mechanical (or robotic) system which automatically transfers parts from tool to tool, and from press to press in a line of press machines. The highest volume tooling (the stamping dies capable of producing 60+ parts per minute) are known as a “progression” tool. They are named as such because many smaller tools are joined together and a sheet metal strip “progresses” thru each tool, using the sheet metal as a carrier to progress the blank from stage to stage at a very rapid rate.

How a stamping simulation can be used to improve quality?

Because of the significant capital investment required to create a stamping die or a set of sheet metal tools, any method which can reduce the risk of malfunction or an un-expected problem, is used as early as possible in the design stage. Sheet metal stamping simulation is used to validate and verify a tool design before any tooling is made, to ensure no unexpected problems are encountered and to ensure the time and money invested produces a successful outcome.

Other Helpful Reading:

Achieve Metal Stamping Success Through Smart Planning and Production

Understanding The Effects Of Oil Canning in Stamping Simulations