5 Ways AutoForm Maximizes Tool Design

Contents

Advanced AutoForm software features allow engineers to design sheet metal tooling processes in 3D without an advanced CAD system. In fact, 3D CAD modelling of tooling is the last step of an efficient sheet metal forming simulation.

When sheet metal forming simulation was first introduced, it was thought that the entire tool had to be designed in 3D CAD as the first step, before a simulation could take place. Furthermore, for progressive type tooling the first step was always to create a full 3D strip model, complete with blank, carrier and stretch web details before any confirmation of a successful forming process!

5 Ways AutoForm Software Improves Tool Design

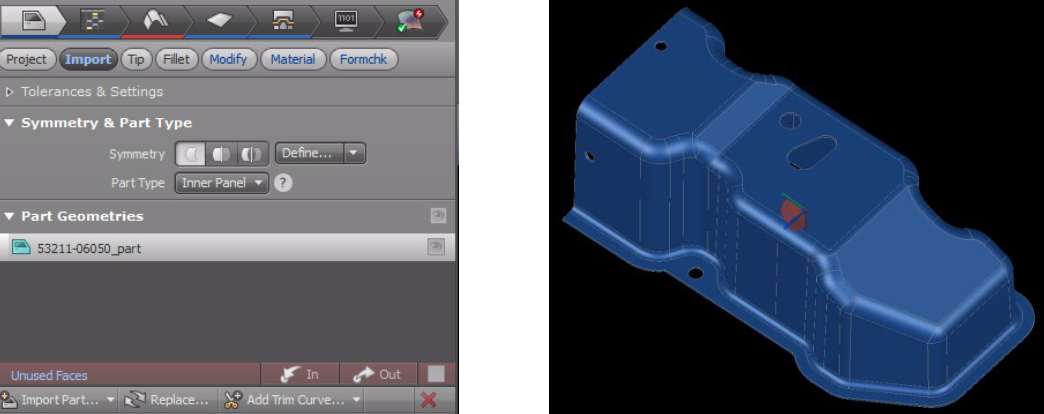

- Only the final 3D product geometry is imported into AutoForm. All tooling shapes/steps are designed using advanced AutoForm-DieDesigner software module, working backwards from final form to first draw and every step in between.

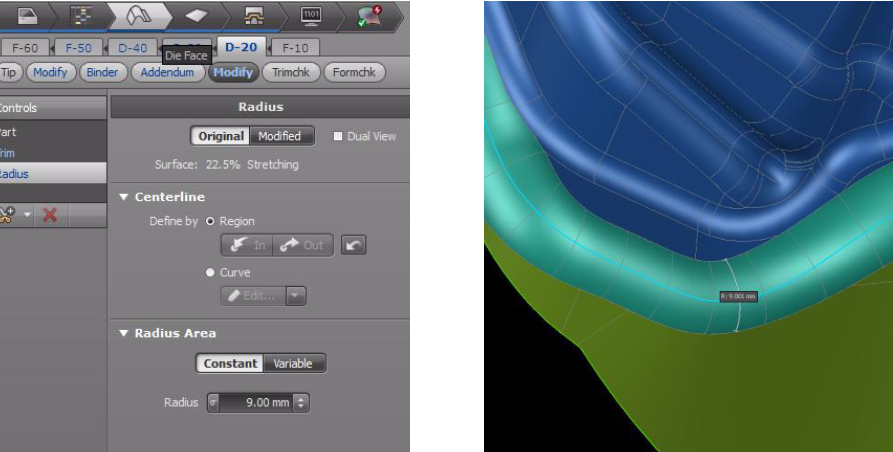

- AutoForm-DieDesigner functions are parametric and hold logical relationships with the model but without the restrictions often found in CAD systems. A whole new approach to 3D modeling is created inside AutoForm without touching CAD, and efficiency is improved many times compared to importing tooling surfaces created in CAD. Needless to say, the geometry created inside AutoForm-DieDesigner is ready for simulation instantly and linked directly to the simulation setup.

A radius in AutoForm can be updated much faster than in CAD.

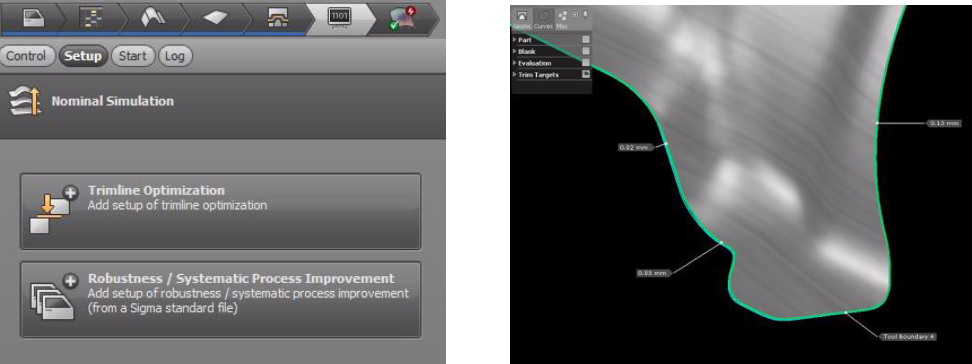

- AutoForm-Trimline Optimization determines the correct blank shape and size using iterative simulations. Stretch webs, blank size, pitch and traditional details are ignored initially for investigative simulations. These details are not finalized until a working simulated forming process is completed. Traditional designers manually calculate (or guess!) the correct blank shape/stretch web/pitch only to find out in simulation their idea was not successful, and must then use large amounts of time re-designing in CAD. AutoForm does this in simulation, without any CAD software.

Trim targets are set during TrimLine Optimization

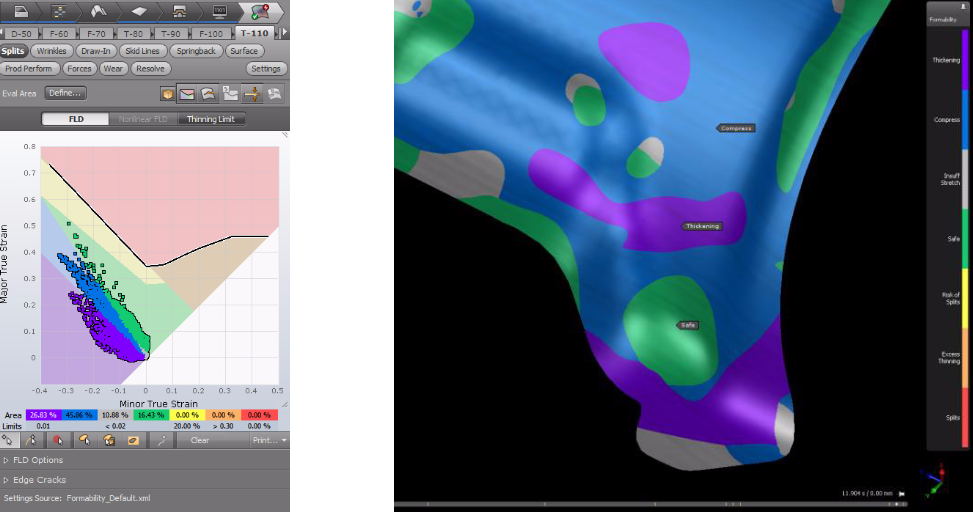

- AutoForm allows infinite definition and evaluation of alternative tooling geometry by simulating over and over again, adjusting geometry many times based on simulation results. The “trial and error” is not only done in simulation, it’s done without an external CAD system. Designs are “safe” only when AutoForm shows no problem areas and is confirmed by a human.

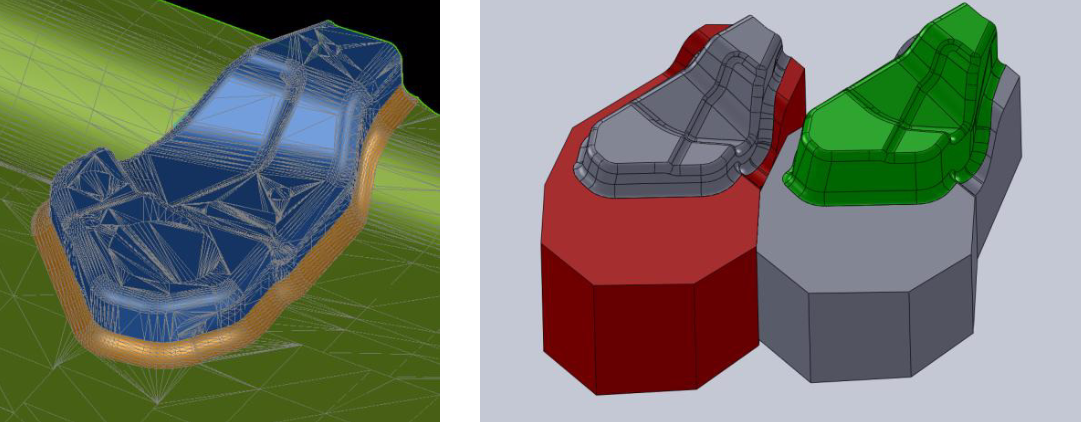

- The LAST step in an efficient AutoForm tool design is to EXPORT the geometry from the simulation. AutoForm R7creates IGS surfaces on the fly based on the FEA mesh used in the incremental simulation. Draws, preforms, developed blanks, stretch webs, carriers, etc, can all be exported and then imported to any CAD system to create the final tooling shapes that have already been proven in simulation.

Geometry created in AutoForm-DieDesigner is exported and turned into solids in CAD as the final step.

Improved Simulation Results

We call the above 5 steps “SimulateComplete”. What used to take days and weeks of switching between CAD and simulation now takes just hours. In a recent benchmark study, we found a pure CAD based approached to simulation took a full 2 weeks to obtain a less than optimized result. When Stamping Simulation approached the same part using “SimulateComplete”, a better result was achieved in just 8 hours.

To learn how AutoForm software can improve your designs, contact us.