Better Results For Your Tooling Projects

How It Works

- 1

- 2

- 3

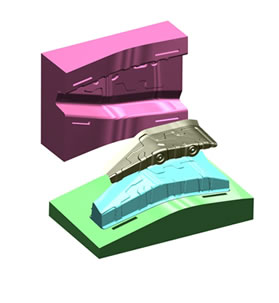

- 4

STEP 1

Provide a 3D model of your design

Send our team the product and/or tooling design geometry by choosing to Get A Project Quote. Your design data will be transferred to StampingSimulation engineers so we can begin assessing your project immediately.

STEP 2

Determine a Forming process

An initial forming process is simulated. We can develop the entire process independently OR we simulate the tooling data you provided. We review with you every step of the way and your input is always requested.

STEP 3

Engineered with simulation

The forming process is tested with multiple simulations, then re-engineered and simulated until a feasible forming process is developed. The final process is determined by iterative development in simulation and always involves more than one simulation.

STEP 4

Results delivered

Once we've successfully engineered a forming process, the requested data outputs are generated and sent to you. The solid tooling data and developed blank shapes (or cutting curves) are provided to you for each forming step, giving your tool designer the fundamental building blocks for a successful outcome at first tryout.

Different Services To Meet All Your Needs

Forming Simulation Services

Forming Simulation ServicesOur on-demand sheet metal forming simulation services allow you to test sheet metal tooling in the virtual world before any tool steel is cut, saving valuable time and resources. Learn more...

Structural Simulation Services

Structural Simulation ServicesOur structural simulations solve challenging engineering problems and help our clients create better products more quickly. Learn more...

Your Partner to Compete in an Evolving World

We believe that success only comes from combining real world experience with the best simulation technology. This is why our teams are composed of knowledgeable engineers that have spent years gaining experience and skills. We find, hire, and train the most talented individuals possible, so your tooling projects get the best people working on them.

At StampingSimulation, your challenge is our challenge. And we take challenges seriously.

Brands We Work With