ANSYS Simulation

Case Study

- Multi Step Simulation- Lodent Precision

- Forming Simulation- Corsair F4U

- Forming Troubleshooting- Die Engineering

- Step Optimization- Die Engineering

- Thinning Prevention- Viking Tooling

- ANSYS Simulation- Premier Tool Design

- Forming Troubleshooting- AFC Tool

- First Tryout Success- Minnesota Tool & Die

- Tool Design Testing- Die Enginnering

- Forming Troubleshooting- Malben Engineering

- Forming Troubleshooting- Williams Tooling

- Forming Simulation – Ustun Makina

- Metal Product Development- Rover Australia

Case Study - ANSYS Simulation

Ansys, Inc. (ANSYS) structural simulations provide fast and accurate finite elements analysis of any type of mechanical loading to any structure of any material type.

This case study shows how Premier Tool Design, LLC was able to correctly determine the amount of deflection expected at the tip of an injection moulding unit due to its self mass. The main mass of the unit slides on two linear rails and overhangs the main structure. Therefore, this raises a concern that there could be too much deflection at the injection point, which may make the unit unusable.

By using StampingSimulation.com’s ANSYS simulation services, the client was able to assess the deflection magnitude and add stiffness to the structure to keep the deflection within acceptable operational limits. Different scenarios, such as extra linear rails, could be quickly and easily assessed in order to determine the best configuration to keep the deflection low.

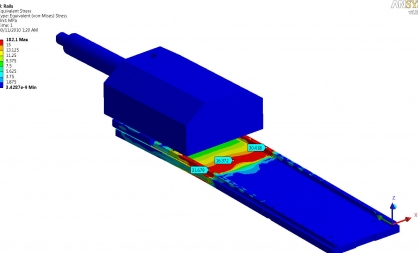

In addition, the induced stresses in the structure can be analysed to determine if the structure will deform permanently or simply flex elastically under the given load. If the stress exceeds the material’s yield strength, it’s clear that the material will suffer permanent deformation and may be unsafe. Using ANSYS simulation, it’s possible to determine the “safety factor” of any structure. In the case of this example, the stresses are well within the material limits and the result is “safe” for the given load. No permanent deformation is expected.

The cost of simulating in the design phase and correctly specifying the structure stiffness far outweighs the cost of an unusable result on the shop floor. Without simulation, designers are forced to calculate by hand or guess how to achieve an acceptable result. Hand calculations often rely on simplifications, due to complex three-dimensional (3D) geometry, and they are not always straightforward. Using 3D solid data, ANSYS can analyse even the most complex assemblies without the assumptions that are often used in hand calculations.

StampingSimulation.com offers ANSYS services on a job-by-job basis to analyze any product, assembly, or structure with loads of any type. Advanced analysis options include determining natural frequency response, nonlinear analysis, fatigue, and cyclic loading analysis.

Premier Tool Design, LLC is a tool and die design firm that specializes in 3D solid designs for the sheet metal stamping industry. They specialize in progressive die tooling but also excel in transfer and line dies as well.

Simulation Videos

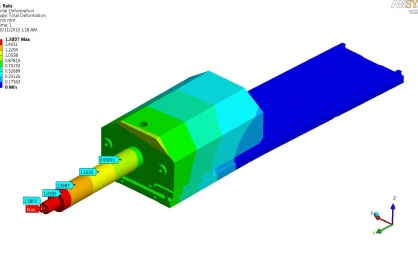

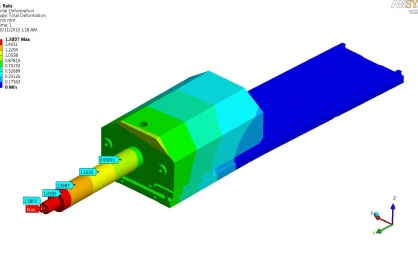

Figure 1: Load Deformation

The color map shows the calculated deformation, due to the applied load, highlighting the maximum point.

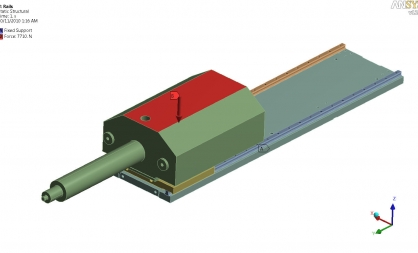

Figure 2: Load Setup

The constraints setup determines where the object is supported and where the load is applied, including magnitude, type, and direction of the load.

Figure 3: Load Stress