How Process Engineering Can Help You Conquer High-Strength Materials

Contents

Similarly to technology, the world of manufacturing and metal forming is constantly evolving. One of the biggest factors to take into consideration is the development of super-strong, exotic materials. Materials such as dual-phase and triple phase steel can help you make durable parts, but they may also complicate the manufacturing process. In this article, we discuss how process engineering and simulations as a whole can help design the best process for these new supermaterials, allowing manufacturers to take advantage of them without it costing a fortune.

Sheet metal parts made from “regular” steel sheets may be considered easy…..most manufacturing companies have an employee or two with enough knowledge, experience, and skills to form a mild steel or mid-strength steel part using “rules of thumb” or previous experience. However, when steel materials reach into the very high strength range (Tensile Strength >500MPa) then forming and drawing is no longer easily predicted by what worked last time.

What Are Super-Strong Exotic Steels?

To expand the definition, “super-strong exotic steels” may include uncoated and coated steels, dual phase (ferrite + martensite) (DP), dual phase with high hole expansion (ferrite + bainite) (FB), transformation induced plasticity (ferrite + bainite + retained austenite) (TRIP or TR), multi-phase (ferrite + martensite + bainite + precipitation hardening) multiphase(MP) or martensitic (MS) materials. These products can be supplied as coils or sheet. All of this sounds like a headache!

…and without a material test and advanced computer simulation, all of these materials are indeed a massive challenge which should not be taken lightly. Thankfully, testing a super-strong exotic steel can be as straightforward as testing a standard grade of steel. The uniaxial tensile test can sufficiently capture the mechanical properties of any grade of steel, from mild to triple phase, from aluminum to titanium.

Running a simulation on super-strong exotic steels is the same procedure as running a simulation on mild steel, only the outcomes and potential savings are an order of magnitudes larger in the case of super-strong exotic steels.

How does your company successfully avoid problems like these in super-strong exotic steels?

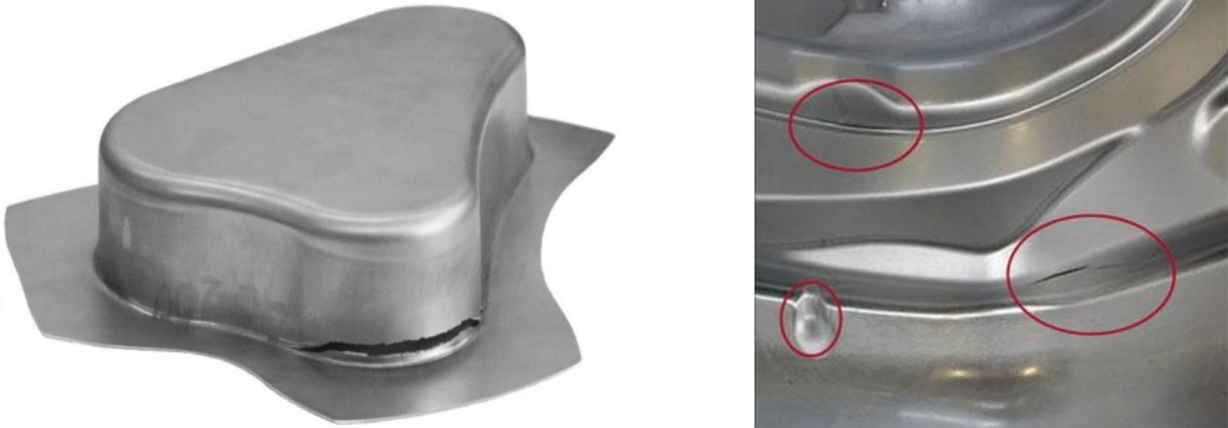

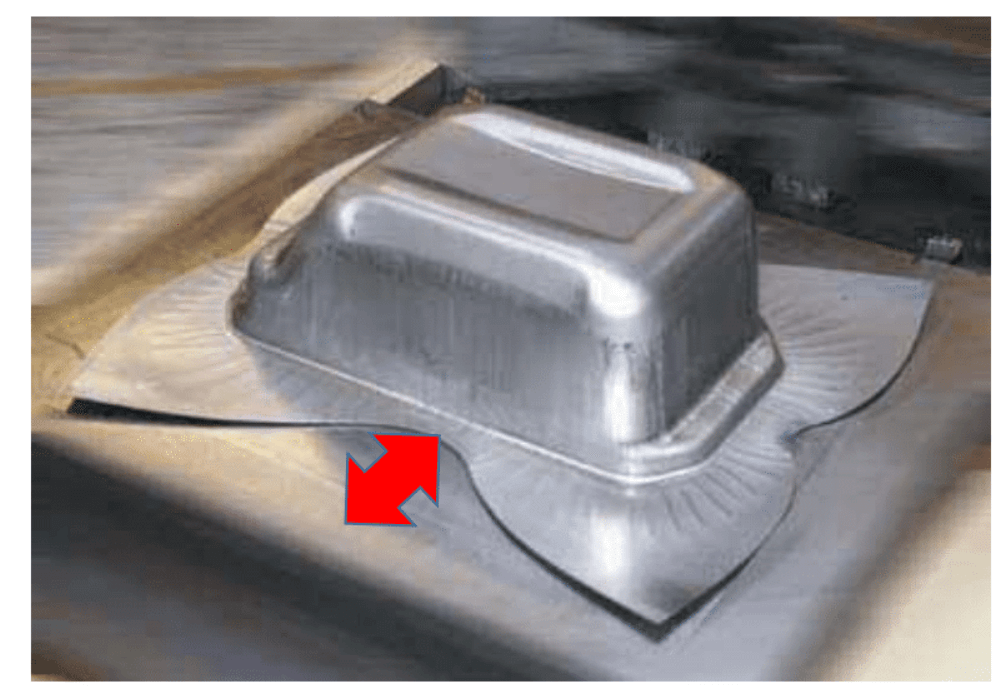

Could this deep drawn part be made successfully in dual phase material?

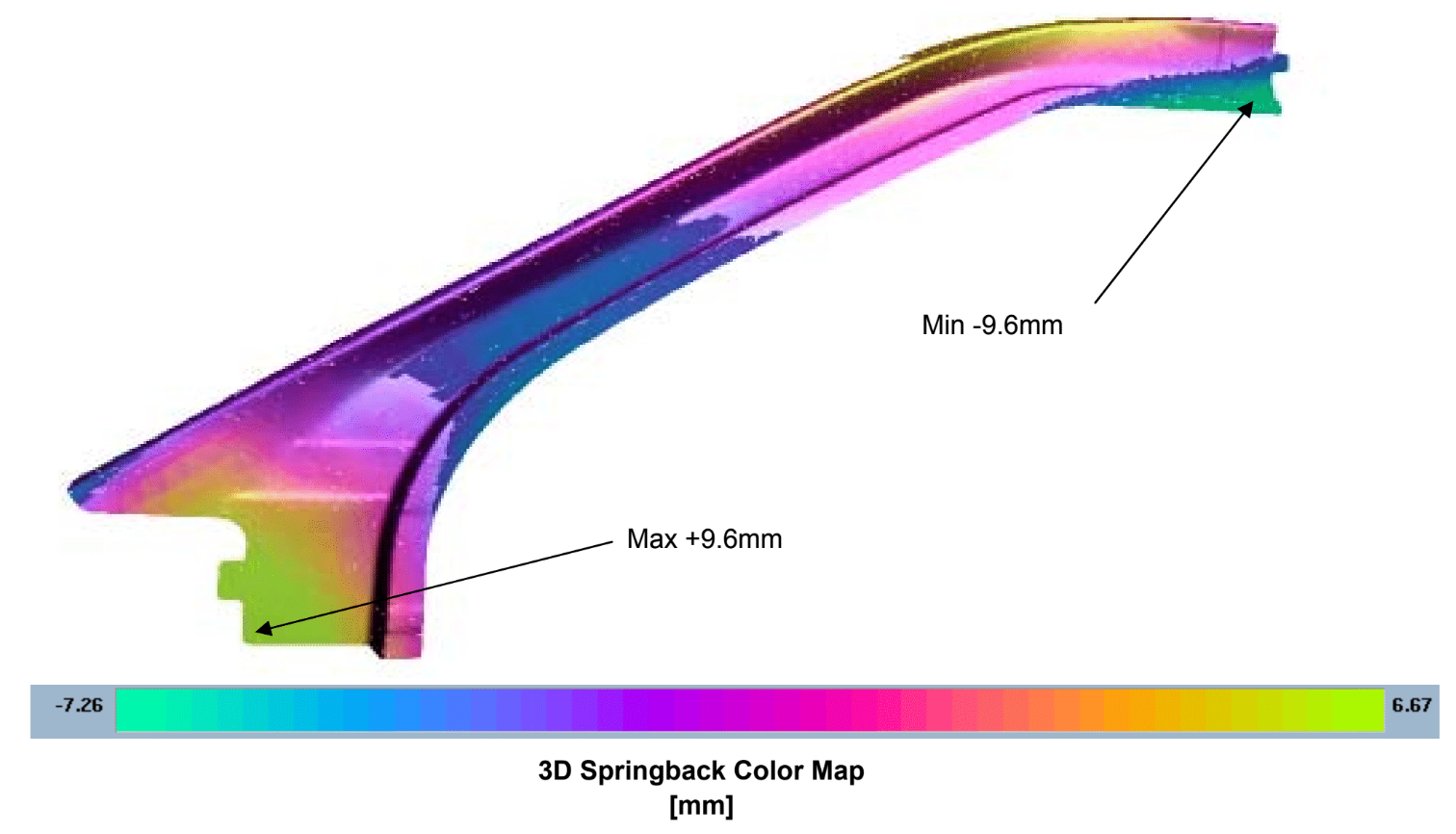

Springback in dual phase and multiphase material can be severe

The key challenge when simulating super-strong exotic materials is understanding the result, and then understanding which countermeasures may produce a successful result. Adjustments used successfully for standard grades of material to fix common problems, usually do not with super strong materials. Additional thinking and a deeper understanding of the problem are required to find a successful outcome for such materials. Thankfully, simulation allows engineers at StampingSimulation to work efficiently and quickly to design, test, and prove ideas that will find solutions to even the most complex forming problem for any material.

Learn More

Interested in learning more about what is possible with advanced forming simulation software? Take a look at a few of our case studies and see what’s we’ve accomplished for our clients.