Forming Simulation Services

Choose from two on-demand service options:

StampingSimulation uses the latest technology to ensure that your simulation project meets your standards.

SimulateLite

Virtual Tryout Service

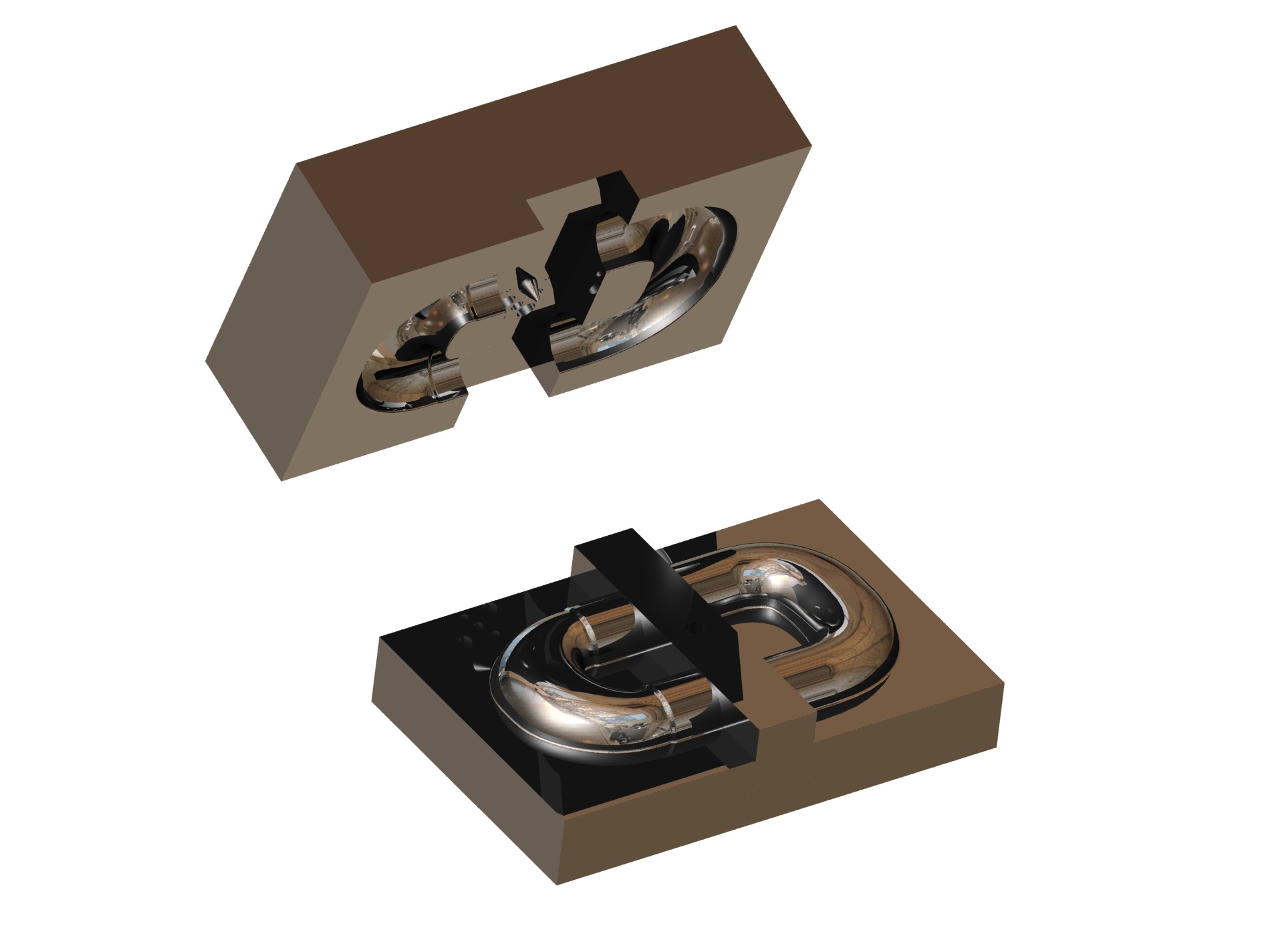

- Test your tool or process design in the virtual world, before any tool steel is cut. SimulateLite® eliminates forming problems before they occur. No knowledge of finite element analysis software required!

- We provide all the software and simulation analysis required.

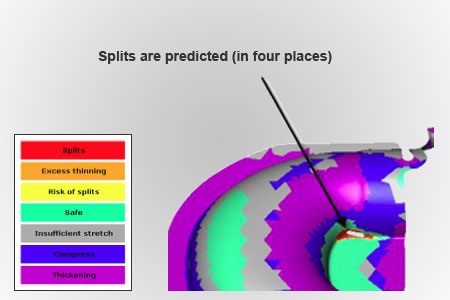

- Problem Prediction

- On Demand Service

- Online 3D Results

- Material Forming Limit Information

- Material Thinning Information

- Up to 3 virtual tryouts

SimulateComplete

Complete Process Design

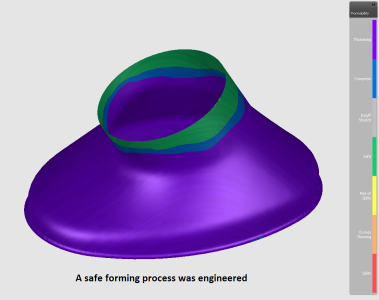

- Your product design geometry (the final part design) is turned into tooling surfaces and used in simulation to engineer a successful forming process, proven in the virtual world. No knowledge of finite element analysis software required!

- We provide complete, comprehensive process design and simulation.

Everything from SimulateLite, and:

- Complete process design or strip layout

- Process re-engineering until a feasible forming process is developed

- Forming forces calculated for each process step, to determine press size and optimal blank holder pressure.

Full Service Options - SimulateLite

- Forming forces, calculated for each process, to help determine press size and optimize blank holder pressure

- Fully developed blank shapes, to decrease blank development time

- Spring back analysis with compensated die face data

- Additional virtual tryouts

Full Service Options - SimulateComplete

- Fully developed blank shapes, to decrease blank development time

- Full data outputs: solid tooling data, upper/lower tooling with offsets.

- Spring back analysis with compensated die face data

- Additional simulations and process design iterations

Brands Our Work Has Enhanced