An Introduction to Tonnage Calculation and How It Affects Your Product Design

Contents

There are many different elements to keep in mind when designing or improving a product. One of the biggest questions is: how exactly will your product be manufactured? What type of blank will be used? Instead of conducting trial and error, professionals use simulations to calculate tonnage and other aspects of your manufacturing process. This article focuses on using simulations to carry out accurate tonnage calculations and explains the different units of tonnages used in the industry.

Tonnage Calculation with Simulation

Manually calculating tonnages for forming processes such as drawing, forming, bending or cutting is a thing of the past for all but the most simple geometries. Anything other than a simple shape or straight line bend requires advanced simulation for the most accurate tonnage calculations.

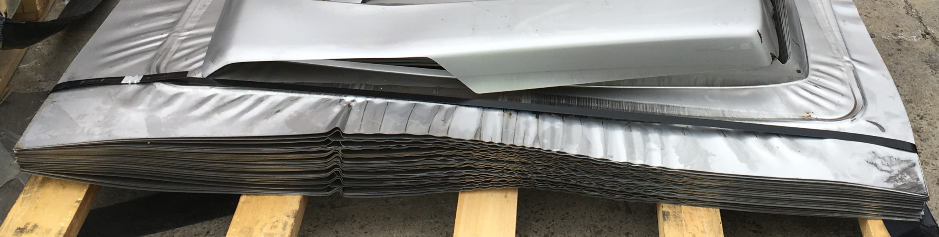

The most common error is to force a tool in a press that is undersized for the job at hand because that’s the only press available! Often, the press machine cushion is under-rated for the job, but “need” and “want” overtake good engineering practice, and parts are manufactured with inadequate binder pressure.

Parts being made with inadequate binder pressure…..wrinkles and moving beads!

We have written many times before about the benefits of using simulation to correctly determine all tooling forces using simulation, prior to tool manufacture. In the rest of this article, we explain the different units and terminology used in the industry with respect to “tonnage”.

Ton OR Tonne OR short ton OR pounds OR kN OR kgf OR Pressure?

The number of different ways to express force in the sheet metal tooling industry is enough to make your head explode! Worse still, the term “pressure” is often used interchangeably with the term “force”, even though they are not the same units!

Here is a quick cheat sheet to explain each:

Ton – a ton is a unit of weight and in America, nearly everything is different to the rest of the world and “ton” is no exception.

Short Ton – typically used in America. 1 Short Ton = 2000 US pounds (lbs)

Long Ton – as called the British ton. 1 Long Ton = 2240 US pounds (lbs)

Tonne – 1 Tonne = 1,000 kilograms (kg). This is the metric tonne. It is rarely used in American English and is often used outside of the USA.

Ton (inside USA) – usually means 2000 US pounds

Ton (outside USA) – usually means 1x metric Ton which is 1,000 kilograms (kg) or 2,204 pounds (lbs)

Newton (N) – The Newton is the standard international unit of measure of force. Force = mass X acceleration (F=ma)

KiloNewton (kN) – 1kN = 1000N. 1kN = 102 kgf (which is approximately 100kg of force)

Therefore, 10kN is approx. 1000kg which is approximately 1 Metric Tonne

In almost all simulation software (even inside USA) the metric system is the basis for all calculations. Therefore, whenever we discuss or report “tonnage” for sheet metal forming it is always calculated as Metric Tonnes.

However, to avoid the confusion between all the “tons” and “tonnes” it is often best to report forces in the true units……Newtons (N) or kiloNewtons (kN), since 1N is always 1N in every country on earth!

Learn More

Interested in learning more about what is possible with advanced forming simulation software? Take a look at a few of our case studies and see what’s we’ve accomplished for our clients.