Tube Forming Simulation Helps Create Quality Products

In addition to simulating complex sheet metal forming, it is also possible to simulate tube forming operations — and not just tube hydroforming. This may include tube end forming operations OR simply tube bending. The tube may be of any cross-sectional shape.

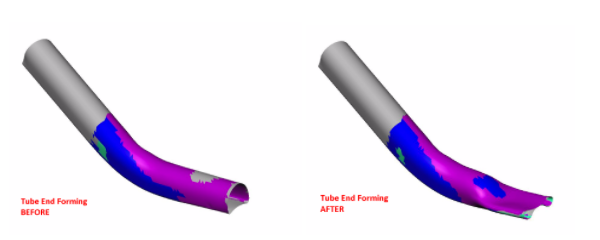

A simple example is flattening the end of a tube. In the same way that we simulate sheet metal, a tube forming simulation uses full incremental simulation and 3D tooling geometry to accurately simulate the process. The full tooling model is part of the simulation, and therefore the simulation input is not complete without the intended tooling shapes for each step of the tube forming process.

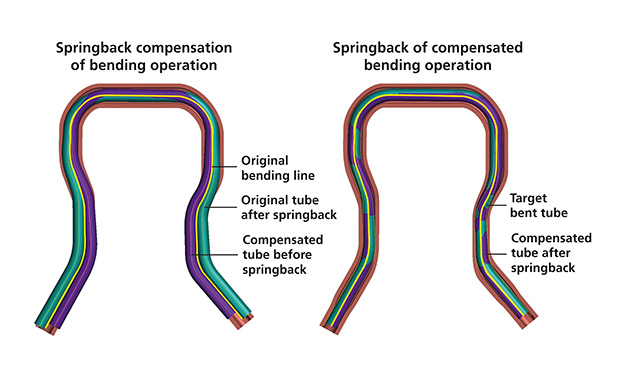

The results are the familiar thinning/thickening, formability, and spring back outputs. In the same way as sheet metal simulation, we are looking for material elements that have exceeded their limits on the Forming Limit Diagram (FLD) or areas that are beyond acceptable thinning limits.

Wrinkles can be found visually or assessed by finding compressed areas. The initial tube section may not be round, and bending operations may precede a forming/flattening operation.

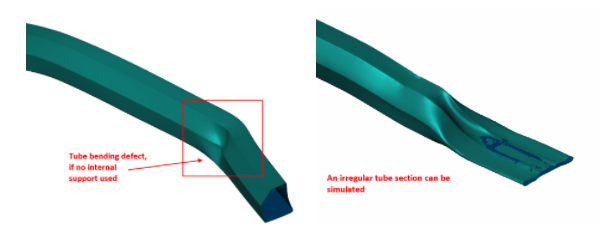

As in reality, tube that is bent without an internal support (beads or springs) may kink or collapse. This problem can be found through simulation.

The benefits of simulating a tube forming process are similar to those that are experienced with sheet metal. Clients who simulate tube forming before investing in tooling reap the benefits of higher quality parts (no unexpected defects), reduced tooling investment costs (less risk of tooling fail), and faster time to project completion.

Many industries utilize tube bending and forming, and those with a great number of years of experiences may not know that simulation is available to perform “what if” scenario analysis, material selection, and product improvement for manufacture. Tube forming simulation helps create parts of complex machines, advanced motor vehicle frames, musical instruments, any product with bent or formed tube.

AutoForm Hydro is AutoForm’s state-of-the-art solution for rapid tool design for all tube forming processes. The latest software version, AutoForm Hydro 2016, offers new functionalities and significant enhancements. The most important one is spring back compensation of bending and hydroforming operations. StampingSimulation offers access to AutoForm Hydro simulation as a service. Contact us today to get a project quote for your tube forming simulation.