Williams Tooling Case Study

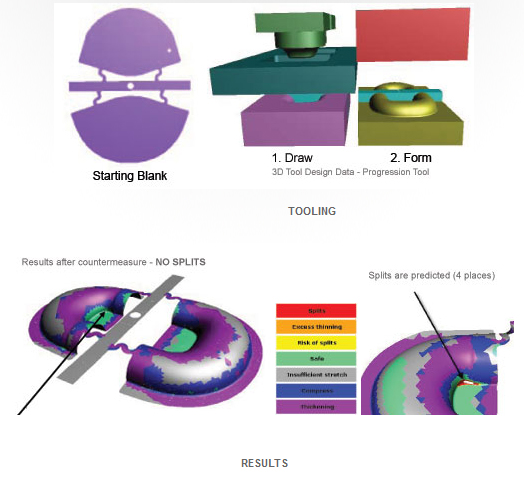

Case Study: Williams Tooling. The client provided solid models of a two stage forming process and required simulation to determine feasibility and blank developments.

Introduction The client provided solid models of a two stage forming process and required simulation to determine feasibility and blank developments.

Simulation Inputs Material Stainless Steel 1.4509 Thickness 1.0mm Yield Stress 296 Mpa Tensile Srength 468 Mpa n value 0.18 r value 1.38 Binder Force (Draw) 1.5 tons Surface Friction Coefficient 0.15

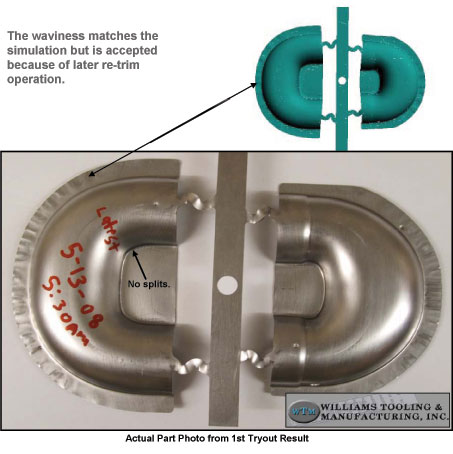

The predicted splits were countermeasured by adjusting the DRAW form shape in the localized problem area and allowing it to be re-struck in the 2nd Form. Using simulation, it was shown that this was a successful countermeasure.

Would you like to be featured in a StampingSimation.com case study?