The accuracy of Simulation

This is the topic that most toolmakers want to know about when the use of forming simulation is suggested. Before discussing this topic, it is important to understand what the intent of forming simulation is.

A common misconception is that forming simulation software is a magical tool that is supposed to replace die designers’ and toolmakers’ years of experience. There is often a misunderstanding that such software can automatically design perfect dies with 100% success. This most certainly is not the intent of forming simulation software.

Forming simulation is a tool. In the same way that CAD revolutionized the way engineers’ design and draft 3D objects, forming simulation is revolutionizing the way toolmakers design stamping dies. As with CAD, the new technology has not replaced the need to have experience and competencies in the core skills of the business. Instead, the new technology enables the designer’s skills to be applied in ways that enable fast visualization of ideas, and fast investigation of design alternatives and allows confidence in the final chosen designs.

So this is how forming simulation fits with the industry. It complements (and does not replace) existing skills enabling fast investigations and checks of die designs prior to fabrication.

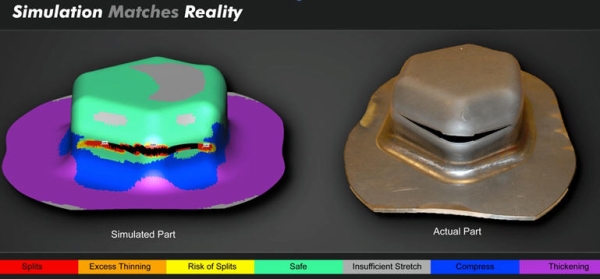

Now back to the initial question. How accurate is forming simulation?

The answer requires an understanding of all the variables that goes into a simulation. A toolmaker with years of experience already understands many of the variables; hence, if he is to perform a simulation and set up such variables according to his knowledge and experience, a very accurate simulation can be performed and the results can be used with confidence.

Conversely, if someone with little press tooling experience were to set up a simulation and choose arbitrary inputs and make pure guesses for addendum and binder surfaces designs, not only will he waste a lot of time, but the results produced will be far from reliable.

How about us? If we are able to help you with your tooling project, what experience do we have? Our lead engineer has worked in the automotive sheet metal stamping industry for six years with extensive experience in die design and part accuracy measurements. After we discovered forming simulation and realized its potential, we started this Web site, to enable all businesses to have access to forming simulation technology.