Simulation yields accurate blank development

Incremental sheet metal forming simulation not only predicts common defects such as wrinkles, splits or springback but is also regularly used to accurately calculate blank shape and trim developments.

In many cases, a sheet metal forming process starts with a 100% developed blank OR requires mid process trimming before final forming. In either case, manually developing the blank or trimming profile is a source of costly try out time, typically taking more than a few days.

Using the AutoForm-Trim module, Stamping Simulation reduces tryout time and cost by optimizing the required cutting profiles via AutoForm-Incremental simulations. This means that every step of the forming process is considered, unlike inverse one-step solutions and therefore, the resulting accuracy is much higher. AutoForm-Trim is an iterative process (used in either SimulateLite or SimulateComplete service options), similar to the shop floor method but entirely in the simulation environment and without the cost of manual labor and press time.

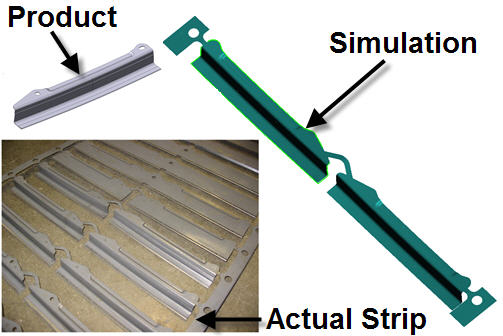

Blank or trim developments are usually solved accurately within a few hours, a saving of many days on the shop floor. [Below: Simulation develops the blank virtually and accurately, through all forming steps.]

This job went very well and the main challenge was the blank development. We were very impressed with the 1st hit of the tool. The result was very close to the required development.” Jeremy Dutkiewicz – Tool Designer Williams Tooling & Manufacturing, Inc.