More than just Simulation

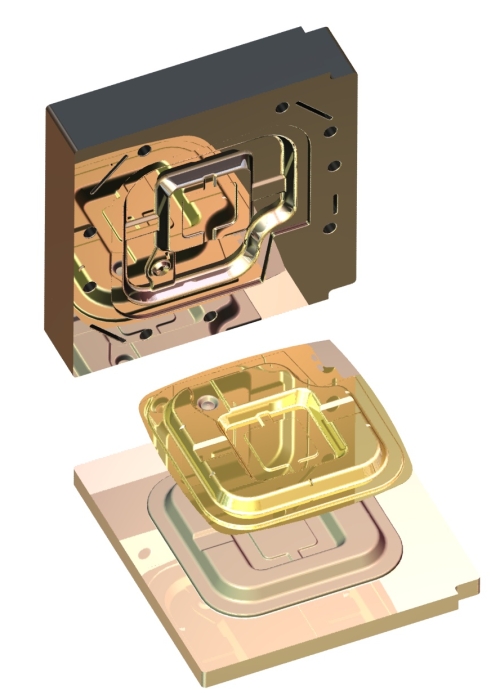

You may not be aware of it, but StampingSimulation.com can provide customers with tooling surfaces (die face data), rather then just a simulation service.

You see, in order to perform a simulation, the entire die face needs to be designed in any case. In most cases, the simpliest die face design is trialled first, usualy a fully developed crash form. Even if it is obvious this tooling method will not work for a particular design, often this type of simulation is performed in any case, because it gives an excellent illustration of what a draw form or draw beads might be trying to achieve.

From here (assuming the part cannot be crash formed), a draw forming simulation is normally performed. This is where the die face design starts to become a little more complicated, as binder surfaces and addendums are now required. If the draw form still shows problems (like wrinkles) then draw beads might be added and simulated and the die face design process continues. Instead of or as well as draw beads, maybe the addedum surfaces will be adjusted or extended, taking into consideration the problems shown in the previous simulation.

Also, it may be the case that instead of adding draw beads, a change in the part design might be more appropriate. For example, to control wrinkling, material soakers (in the form of a rib or two) might be added in the region of wrinkling. Of course once added, their success can be measured by way of simulation.

So the end result for the customer is a trail of simulated die face design development, showing the problems at each stage along the way and how they were overcome.