Improve Your Sheet Metal Trimming Process Through Enhanced Simulations

Sheet metal trimming is a basic process used for thousands of products; however, not all factories start with an optimized trimming process, which may hinder the development time and cost of a new stamping project. We discuss how simulations optimize the sheet metal trimming process, which results in better product quality and reduce operating costs, by virtualizing the trimming development early in the design phase.

Sheet metal product shapes are ever more complex and the geometry of a modern sheet metal part makes it very difficult to determine the trimming profile required, before bending or flanging or forming. It may have been normal in the 1990s to develop the trimming profile by shop floor trial and error, but today the manual method is inefficient and costly. Only companies that utilize advanced trimline optimization via simulation can compete in the modern world.

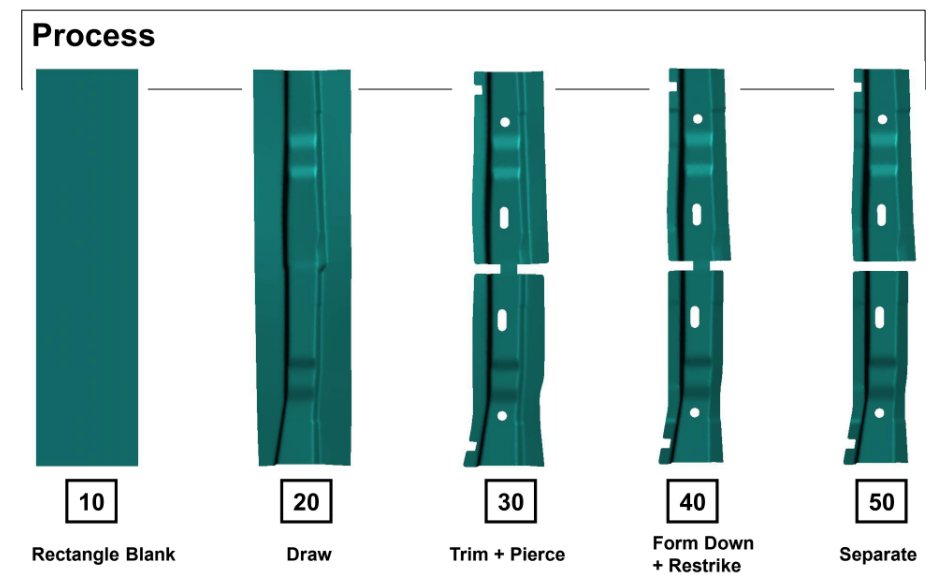

Generally, a trimming process is required before a flanging or bending operation, and usually after a draw or forming operation. In some cases, the trimming may be required before any forming/ bending takes place. In this case, we would say the blank is 100% developed. Either way, or whatever the process, the required trim or blank profile must be developed.

How do you determine the correct trimming profiles and process steps to make this part?

For simple parts, modern CAD software may implement the “one-step inverse method” to flatten a formed or bent part, but results are rarely accurate and only valid for simple parts.

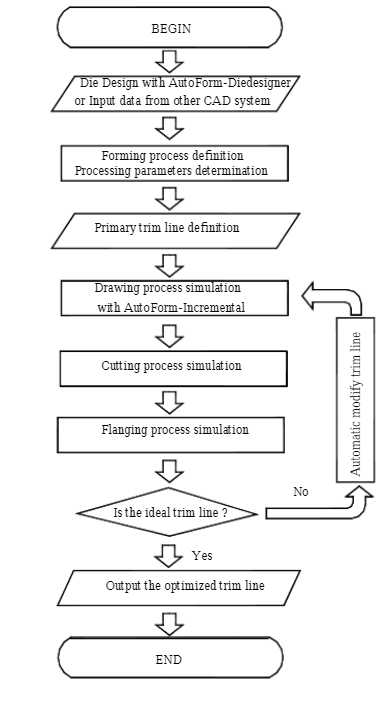

For complex parts, and multistage process parts, a more advanced method is needed. The best way to show and explain how AutoForm advanced FEA software successfully performs trim line optimization is by way of this flowchart:

Source: https://www.researchgate.net/publication/257519626_Optimization_of_trimming_line_in_sheet_metal_forming_processes_by_FEM_simulation

The key to the success of the AutoForm trimline optimization is the automated iterative loop. This extremely powerful automation is a tool that cannot be replaced with any traditional methods or shop floor experience.

StampingSimulation utilizes the full automation of AutoForm trimline optimization to make your sheet metal forming process a success, in record time and at a competitive cost. If your competitor is using AutoForm, you are already behind the competition!

The TRIM+PIERCE operation was developed with AutoForm simulations, prior to tool design and was accurate to within +/-0.2mm at first trial.

Want to Learn More?

If you are interested in how StampingSimulation can help you optimize your process for any sheet metal project and get ahead of your competition, contact us today.