Identify and Resolve Flaws with Your Products Through Root Cause Analysis

Contents

There are millions of products out on the market, and consumers are the ones who dictate their success. Manufacturing facility managers are always looking for ways to improve latent flaws with their products or with their manufacturing process – root cause analysis can help identify and solve these flaws.

Root Cause Analysis Used to Identify Product Flaws

In some instances, the cause of product defect or failure may be obvious and resolving the issue in the manufacturing process may be elementary. However, in many cases product defects may be hidden OR it may be difficult to find the true root cause of the defect. Resolving a defect in manufacturing without understanding the true root cause of the problem usually leads to the same defect occurring on a larger, and more costly, scale.

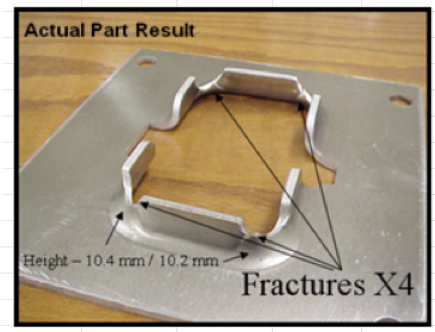

What is the root cause of the fractures in this sheet metal part?

In the case of sheet metal products, defects may be understood more thoroughly by performing physical circle grid analysis on the shop floor to better understand the root cause of the forming defect, such as splitting or excessive thinning. A uniform pattern of circles would be etched on the blank prior to forming, and the amount of strain would be measured by precisely measuring the elongation of each circle in two directions. The resulting major and minor strains could then be plotted on a Forming Limit Diagram to determine where and why the region failed. Once the failure mode was determined, then the root cause of the problem could be addressed correctly, without guessing.

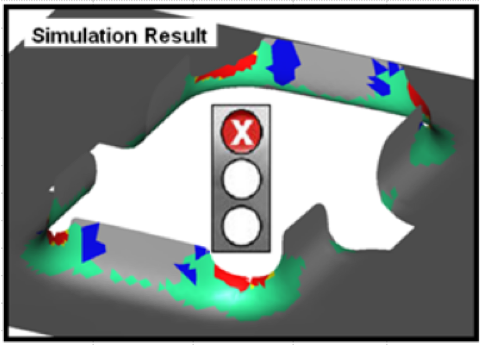

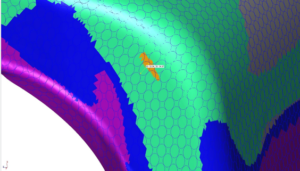

Using advanced simulation technology, the same root cause analysis can be performed in the virtual world, before a product goes to manufacture (OR even after!) The advantages of using simulation to resolve forming issues are significant, since the clarity and speed of gathering information such as major and minor strains, is superior to physical data collection on the shop floor.

Two examples of circle grid analysis in simulation:

Even better, when advanced forming simulation is used to discover product defects early in the design phase, then common sheet metal defects never make it to production. Root cause analysis using simulations significantly reduces and often removes the need for root cause analysis on the shop floor.

Learn More…

Interested in learning more about what is possible with forming simulation software? Check out some of our case studies here.