Hydroforming Sheet Metal: Common Applications and Benefits

Sheet metal hydroforming is becoming a popular option for manufacturers across the globe. Not only does it provide high-quality products, but hydroforming is also relatively affordable. This article discusses the basics of this type of sheet metal forming—how it works, what it can be used for, and the benefits of implementing this process, by way of a popular example.

The best example of sheet metal hydroforming in the mainstream media is from the popular TV show Mythbusters. In this episode of Mythbusters, Jamie needs to create a float for a bicycle style paddle wheeler, in competition with Adam. Although not one for investing in high tech simulations prior to fabricating an idea, Jamie manages to somewhat successfully hydroform a pair of flotation devices from sheet metal, using little more than water pressure and half inch plate steel.

The 1st attempt is not actually using the hydroform method, but rather a mechanical shaping attempt, which fails badly but this leads to the hydroforming methodology…..eventually! View the video here: (non-English, but the images tell the story nicely).

Attempts at sheet hydroforming with a pressure washer – Mythbusters

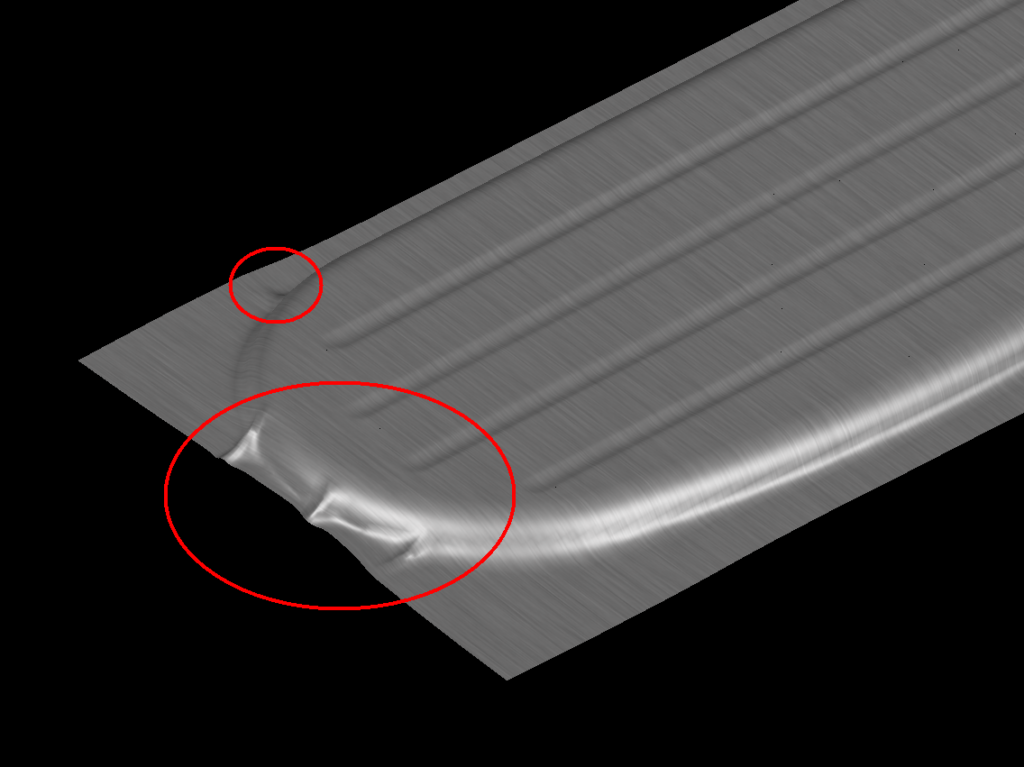

The 2nd attempt is to cut two oval shapes from sheet steel and then weld the perimeter. Jamie attempts to hold the welded sheets between two plates, secured together (and providing clamping force to the sheet edges) by many bolts around the periphery. When hydro pressure is applied (via a very basic water jet pressure washer), the sheet lets go from the bolted fixture, and although the end result resembles an inflated objected, there are serious buckles and there is no control over the final shape of the product.

This is not a successful method, because the hydro pressure attempts to draw the material from the perimeter, which is not secured by more than an inch of clamping area, and thus, as soon as the clamping pressure lets go of the sheet, buckles and wrinkles occur.

The 3rd attempt (perhaps there were more?) uses a full rectangular sheet, and the bolts secure both the steel plates, together with a single sheet of steel. The bolts effectively lock the perimeter of the steel sheet, and when the water pressure is applied, the material is stretch formed by the hydro pressure.

This results in a nice looking part, without wrinkles, even if there is no exact control over the shape of the final product. This a successful hydroform without any specialized equipment.

Successful hydroforming – by restraining the sheet 100% and stretching the material

If Jamie had use hydroforming simulation, he could have arrived at the final result at his first attempt in the workshop. Although the trial and error method delivered a successful result, the time cost was significant (but great for TV entertainment!)

Although the methodology was sufficient for the required product on Mythbusters, most production hydroforming machines can deliver much more precise parts, by using a solid female tool and a flexible upper pad, to form the desired shape exactly. More details about commercial hydroforming are explained in past articles from Stamping Simulations past blogs. Sheet hydroforming simulation will find edge wrinkles when the sheet is not restrained correctly.

Sheet hydroforming simulation will find edge wrinkles when the sheet is not restrained correctly.