How to Accelerate Production Through Enhanced Process Design

Contents

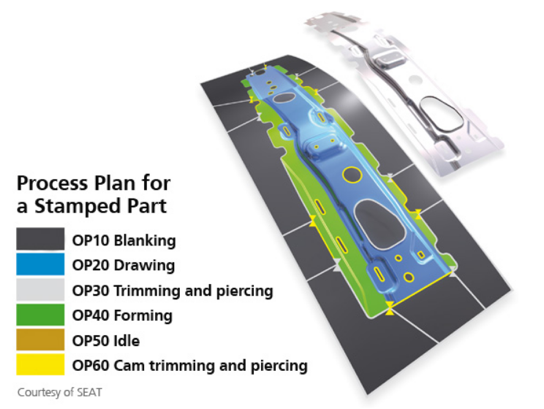

Process design plays a vital role in the functionality and efficiency of any manufacturing facility. There are numerous steps factory managers can take to enhance process design and increase productivity, like changing the layout and getting specialized machinery built. The same applies to sheet metal tooling, where the process planning phase is critical to decreasing tooling lead time and cost, and avoiding costly metal forming problems.

Enhanced Process Design Accelerates Production

Poor process design and planning usually hinders manufacturing lead time, cost, and quality. Therefore, understanding the correct process to manufacture a sheet metal product is of the highest importance. Furthermore, product and process design go hand in hand to truly optimize cost and lead time.

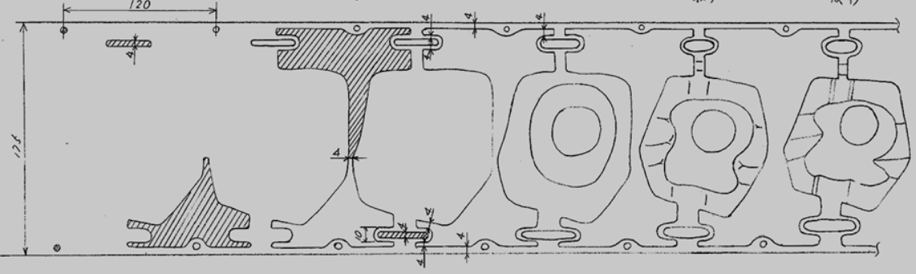

In generations past, process design was done on paper or perhaps not at all, when the given product shape seemed simple. But today’s modern product designs and materials do not allow room for error, and process planning is best done by advanced computer simulation software, with a competent engineer operating the software.

Process planning by hand sketch. Will the blank/carrier perform as imagined?

Advanced computer simulation software allows a process design to be tested over and over before committing to a manufacturing method. The proposed process can easily be modified, adjusted, deleted, added, rearranged, simplified or turned on its head in a matter of hours inside the 3D space of virtual simulation software. Although simulation software will not automagically “find” the working solution, simulation will allow an experienced engineer to test all the possible options to find the optimized process solution in a considerably short space of time.

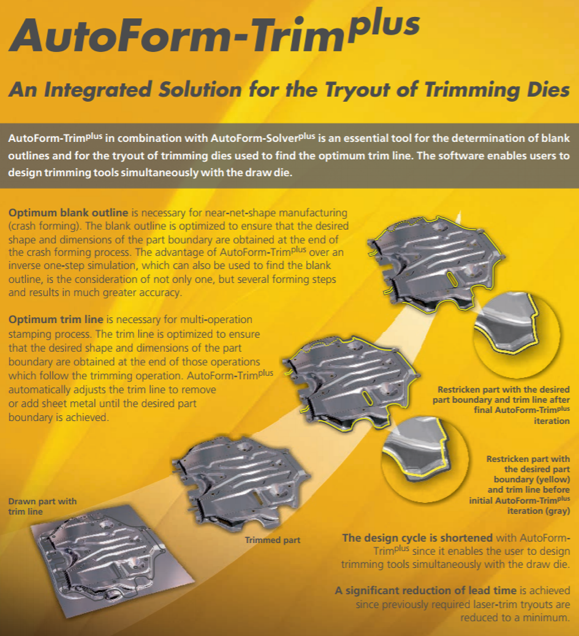

Simulation software will also perform tasks that are not humanly possible, particularly with respect to complex sheet metal product shapes. For example, advanced simulation software – such as AutoForm-Trim – can correctly developed a blank or trim shape to the required target for even the most complex 3D form shape, an otherwise cost and time prohibitive process if done on the shop floor.

Another example is springback. While a traditional tool designer may understand that a springback problem is likely to occur in the proposed process, only advanced simulation software can quantify springback direction and magnitude without building any physical tools. As a result, the correct process steps which allow for correcting the springback problem can be included upfront, such that there are no nasty surprises or extra tooling requirements at the end of the project.

Using An Enhanced Process Design

StampingSimulation engineers use AutoForm to investigate, design and optimize sheet metal forming process plans for any sheet metal product, including the removal of (by design and simulation upfront) common defects such as splits, wrinkles and springback. To learn more about how we can improve your design process, contact us today and let us go to work for you.