How Rapid Prototyping and Simulation Can Improve Your Product Development Process

Contents

Developing a new metal product is crucial, especially if you are looking for investors. Traditional product prototyping may take a significant amount of time, especially if the first model is not close to the desired outcome. We discuss the benefits of fast prototyping and how simulations can help achieve a fast turnaround without sacrificing quality or increasing costs too much.

Product Development Improved with Rapid Prototyping and Simulation

Sheet metal prototyping is still a necessary part of every sheet metal product manufacturing project. Vehicle prototypes are heavily relied upon for crash test safety worthiness and accreditation, and therefore the sheet metal prototype parts must reflect the same condition as the manufactured part, without defects. The formed sheet metal product must be from a sheet of material, and can’t be 3D printed, for example (although the forming tools may be!)

Perhaps an exception in the industry may be with respect to trimming/cutting. A 3D laser part (or NC machined) is still the norm at prototyping part stage in the sheet metal industry. But, if a complex sheet metal part for prototyping needs forming, there are not many options other than to mechanically form the part, as will be done when the product goes to mass manufacture.

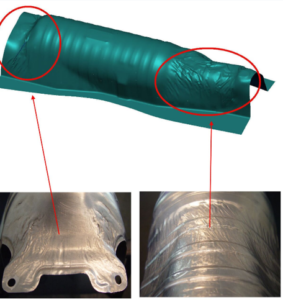

Therefore, all the same challenges of metal forming are present at the proto part stage of any project, and since prototype part making is usually expected to be fast and to a tight schedule, forming a sheet metal proto part without defects (such as splits, wrinkles or severe springback) is just as critical as at any other stage of the project.

This is why simulation is needed at the prototype stage of a sheet metal part. Since simulation is far more efficient (both with respect to cost and time) than the trial and error method, simulating the forming process prior to proto part making makes perfect sense. The added benefit is that any simulation done at the proto part stage can also be pushed forward to the mass manufacturing process, saving even more time further down the project timeline.

Contact Us

Here at StampingSimulation, we investigate, design, and optimize sheet metal forming process plans for any sheet metal product. Using rapid prototyping and simulation software, we find and remove common defects such as splits, wrinkles and springback. To learn more about how we can improve your design process, contact us today.