How does Simulation show wrinkling?

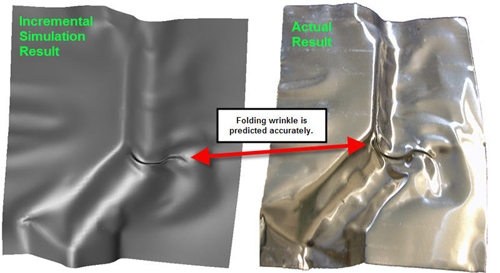

This is a good question and certainly worth further discussion. When assessing wrinkles in forming simulation, it is important to understand how a wrinkle is “displayed.” A serious wrinkle (i.e.: metal folding, scrunching together) will show up very clearly. If the material is predicted to fold, within the FEA mesh of the simulation, folding will be observed very clearly.

If the material is predicted to fold, within the FEA mesh of the simulation, folding will be observed very clearly. This is an example of a serious, folding wrinkle found with simulation.

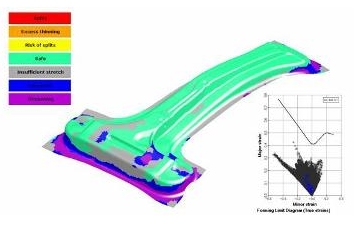

Note that the ability to visualize a wrinkle in this manner is unique to full incremental forming simulation technology, that is, one-step-based solvers are unable to show a wrinkle in this manner. Surface waviness (“wrinkles”) is usually detected via the formability color scale (see Figure 2 below) and is usually very minor, with the purpose of the scale being the detection of even the smallest of imperfections so that an automotive A-class skin panel finish can be achieved. When the colors BLUE and PURPLE are used, the direct meaning is that the material is COMPRESSED or THICKENED and not necessarily “wrinkled”.

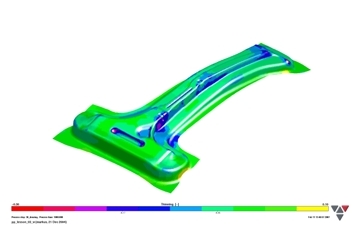

Usually, metal thickness (see Figure 3 above) is also studied along with formability to determine if an imperfection exists. E.g.: material may show BLUE but actual thickening may be 0.1% of metal thickness or less, which does not indicate a “wrinkle” or surface defect for non-skin panel products.