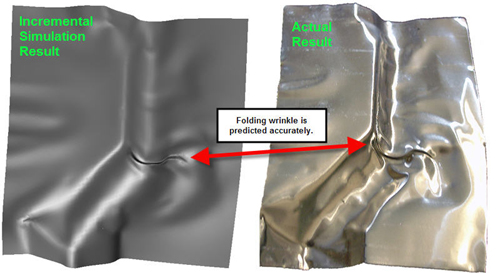

Folding wrinkles accurately predicted using simulation

Sheet metal forming simulation has proven to be accurate time after time. Why then, does the industry hesitate to simulate upfront and save time and money on the shop floor at the end of the project? Those who do reap the rewards.

This example shows the output of a SimulateLite job where a crash form process was proposed.

The simulation clearly predicts a large folded wrinkle as the major problem with this process. The consequences of tooling this process could not have been confidently predicted upfront, without sheet metal forming simulation technology. See our work here.

In this case, StampingSimulation.com was able to engineer a solution which involved drawing metal with a binder, instead of crash forming.

Thankfully, the actual result you see was not a result of a bad process being tooled, but rather, this is a scaled-down soft tool that was created to demonstrate how accurately this problem was predicted.

If you have any questions contact us today!