How Does Accurate Quoting and Process Planning Lead to Success?

Process planning is a key part that occurs before the actual manufacturing or assembly stages.

Through adequate process planning, you’ll be able to determine how much material is needed, the quality of the final product, and many other details that can help you make the best decision.

This article talks about the importance of effective process planning and, subsequently, accurate quoting for the success of your sheet metal manufacturing project.

A good way to illustrate the importance of upfront process planning is to consider an example.

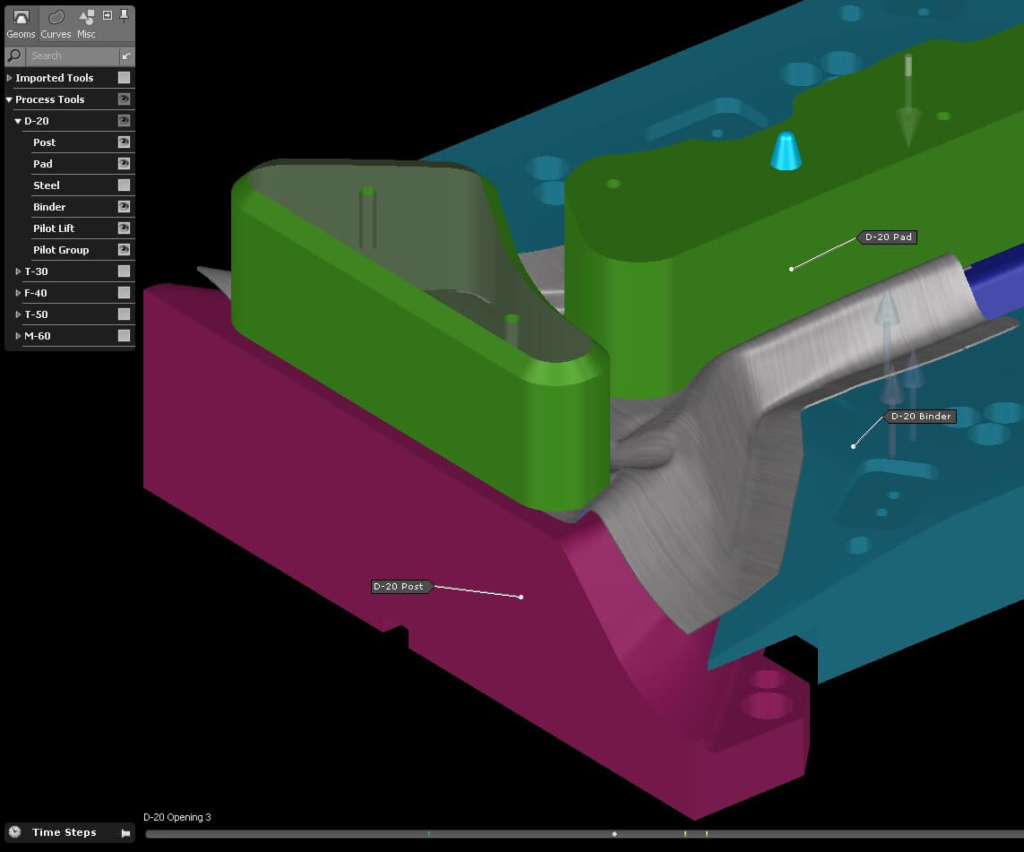

For instance, in a typical draw tool, a pressure pad (or binder) is used to clamp the blank and control material flow to create either a stretch forming condition and/or a draw forming condition. This is well understood and simulation is used to optimize the process.

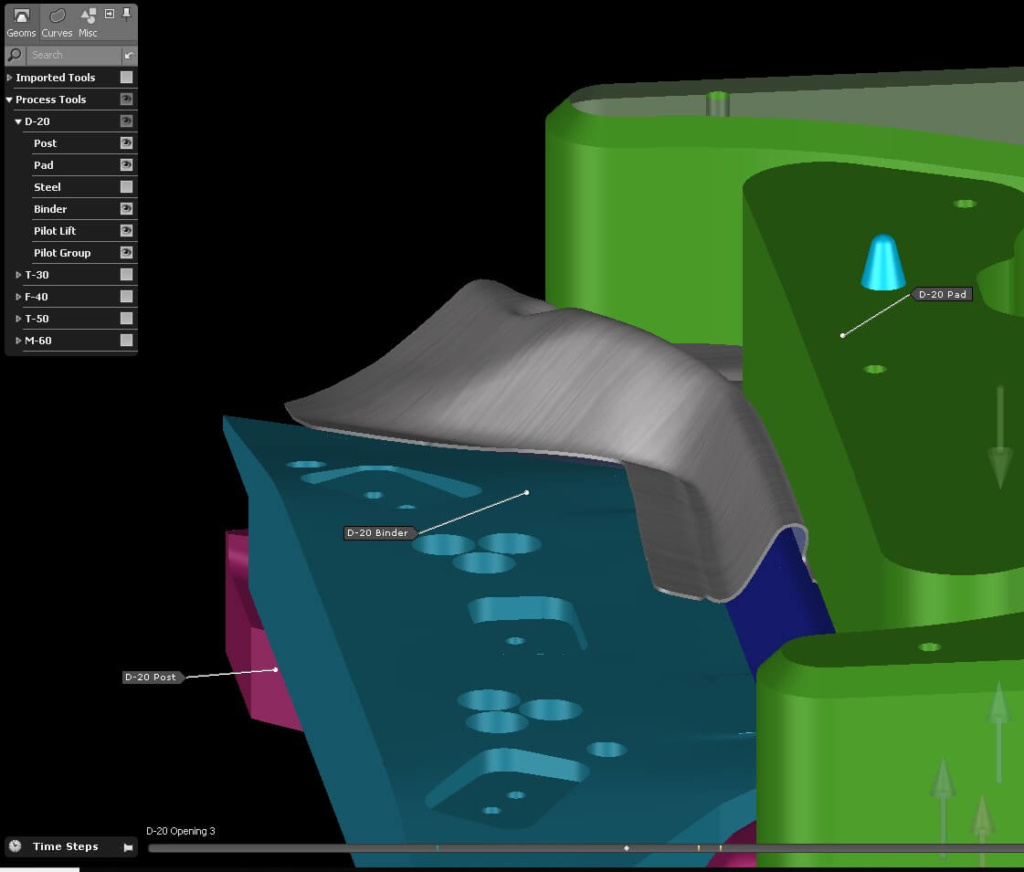

In certain situations, an opposing pressure pad may also be required in a draw tool. That is, a pressure pad on the opposite side of the tool, which is used to firmly hold the sheet metal in place, whilst the draw pad (or binder) does its work. It’s often discovered, in the case of a complex draw with a complex shape, that another area of the part is not controlled, and thus another pressure pad is added. This can be done quickly and easily in simulation.

But the entire simulation is focused on the closing of the tool, and all effort and resources are put into making the process successful for the downstroke of the press, where all the complex metal forming takes place.

However, is the upstroke (tool opening) considered? What about that opposing pressure pad that was added to form the part successfully? What happens if the process planning does not consider the tool opening stroke?

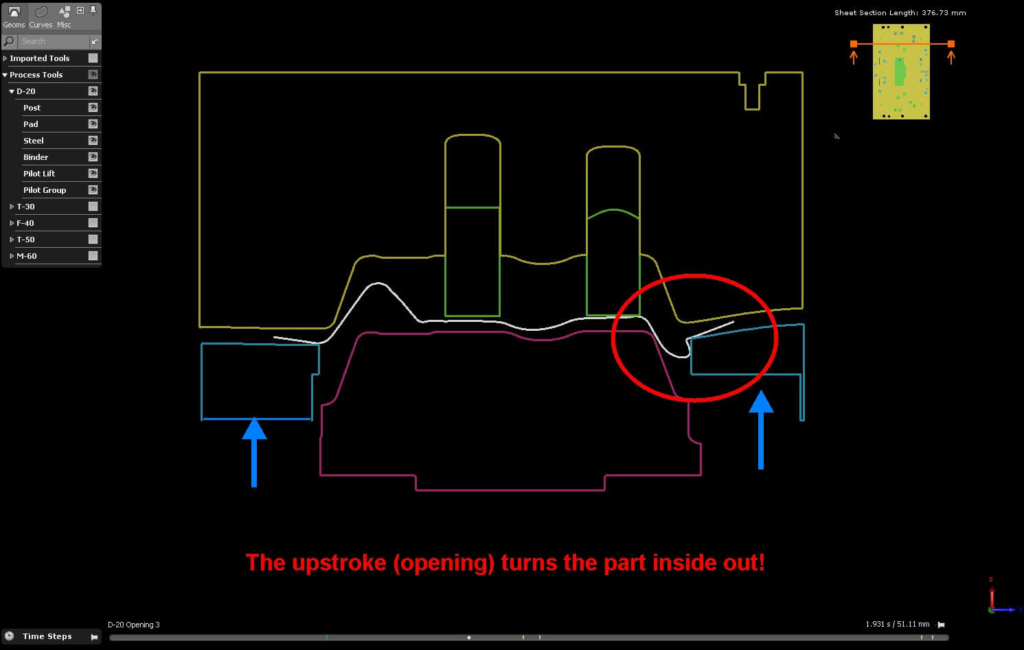

In many cases, the tool opening is straight forward but engineers beware of complex draws with opposing pressure pads. A process plan that works great during the closing, could be a disaster as the tools open. The opposing pressure pad (assume it is upper), in some cases, will apply pressure to the sheet whilst the lower pad (binder) is lifting the part during the tool opening or upstroke of the press.

This may turn the part inside out, and create useless parts.

Therefore, accurate and fast process planning is critical for both the press closing operation AND the press opening operation. It could be quite costly to not consider both in the upfront process planning.

AutoForm allows simulation engineers to easily simulate the opening AND the closing operations quickly and accurately, assessing the outcomes of the overall process plan. This way, successful process planning will lead to successful parts in the press.

If you have any questions or would like to get a project quote, contact StampingSimulation today!