Explain the difference between One-Step and Incremental Simulation technology

It is important to understand the difference between the calculation methods used in sheet metal forming simulation. The term INCREMENTAL and ONE-STEP refers to the calculation method used to solve the forming simulation mathematics of a sheet metal forming simulation problem. It is important to understand the difference between the two calculation methods and to understand when it is appropriate to use each method.

ONE-STEP – a single-step calculation that completes very quickly (in one step). The primary input is a CAD model of the final part geometry. No tooling geometry is considered. The result is a single picture of the final part shape, without all the “incremental” steps between a flat blank and a fully formed part. Only a single process can be calculated by using this method. Just about all blank shape calculators use this method to calculate an initial blank. No consideration is given to the process used to form the part, but it is loosely equivalent to a single-stage crash form.

The ONE-STEP method is appropriate only for approximate results when time is of the essence and results are needed quickly. This method is most appropriate when a part is to be formed in a single-crash forming process, from a 100% developed blank. Apart from this specific case, it is best considered an approximation only. It is used extensively at the quotation stage of a new press tool project.

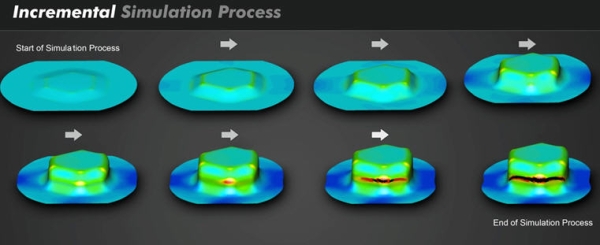

INCREMENTAL – a calculation method whereby every step of the forming process (from flat metal to final form shape) is considered and calculated in “incremental” time steps. The primary input is complete surface models for every forming step in the process. Using this method, a complete simulation of the forming process is generated very accurately, outputting forming limit and thinning information as basic results, for every “increment” of the forming process. More than one process can be considered when using this method, but it can also be used to simulate a single-stage forming process more accurately than a ONE-STEP calculation. It is most appropriate when multiple forming stages need to be simulated accurately. Furthermore, very accurate blank developments can be achieved through multiple forming processes by using incremental forming simulation. It is used whenever reliable accuracy is required.

StampingSimulation.com always uses the INCREMENTAL simulation method when performing full sheet forming simulations services.