Early Formability Checks Developing an Efficient Design Before The Production Stage

The most successful companies tend to deliver top-notch products the first time. While there is always room for improvement, it’s very important for companies to deliver safe and efficient products right off the bat in order to make a good impression with consumers. Metal forming simulations can help assess the feasibility of a product design and the materials used. This article explains how simulations are used as an effective product design tool before the product ever hits production stage thanks to formability checks and other related simulations.

Imagine you are designing a complex 3-D product that requires deep drawing—let’s say a lawn mower deck. The new product design calls for the deepest product shape ever designed. Research into the current product shape shows it requires TWO draw stages to achieve the current product depth in production. However, the company CEO and bean counters (aka Financial Controllers) have decreed that the budget only allows for one draw tool.

How will it be possible to design a deeper product shape, and manufacture it with only one draw tool?

Answer: Stamping Simulation and AutoForm Incremental sheet metal forming simulation software.

At any stage of the product design, sheet metal forming simulation software can be used to assess the feasibility of the product design. If the goal is to minimize cost, reduce tooling stages, and optimize material yield (blank size) then the sooner simulation is utilized, the more optimized the product design becomes to achieve those goals.

For example, we can see how this lawn mower deck (courtesy of Rover Mowers Australia) achieved the desired outcomes. The new product shape was optimized in the design stage to ensure the depth and complex shapes could be achieved in manufacturing with just a single draw.

Simulating after each design iteration enabled the product design to evolve into the optimized shape for deep drawing, which is such a challenging part. Results from the simulation were feedback to the product designers, and changes were made accordingly. The cost of modifying the design early in the development stage is 10% the cost of modifying the design after tooling is made.

The results speak for themselves.

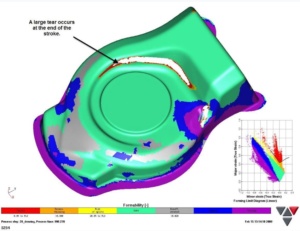

Product Feasibility – Version 1

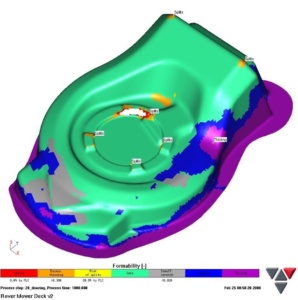

Product Feasibility – Version 2

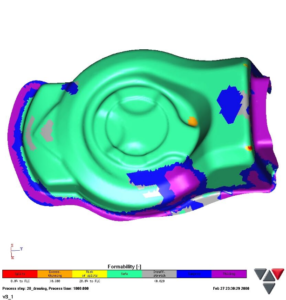

Product Feasibility – Version 3.1

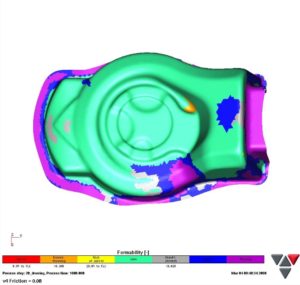

Product Feasibility – Version 4

The final result in reality

Stamping Simulations can help with your next project that requires metal forming. Contact us today for more information.