Does increasing material thickness reduce the risk of splits?

The best way to answer this question is via the Forming Limit Diagram (FLD). The colors and predictions of splits/compression, etc., are all based on the the FLD

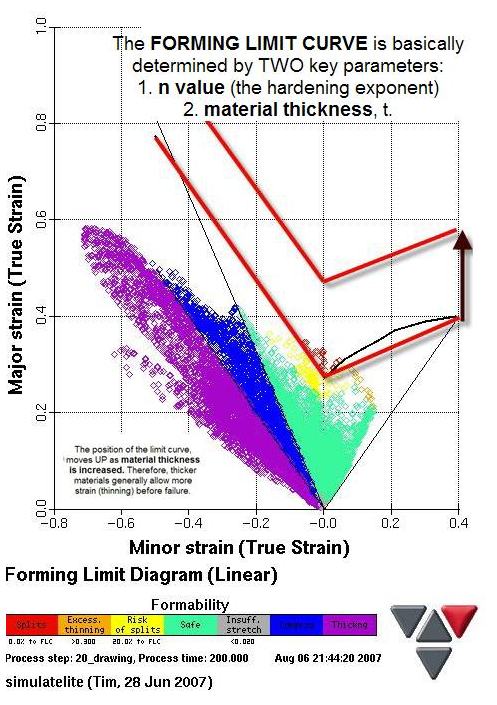

Figure 1 below shows an example FLD, with the various colors plotted for an arbitrary part.

It was established a few decades ago that metal forming limits can be predicted by using the FLD and there are TWO key parameters that set the position of the limit curve. One of these is MATERIAL THICKNESS.

As material thickness INCREASES, the limit curves moves UP the Y axis and therefore, the limits of the material are greater. That is, a thicker material will accept (tolerate) more strain before failure occurs. This has been proven many times in simulation and the real world.

To remove any risk of splits, one possibility is to increase the material thickness. HOWEVER, this is usually undesirable because this also increases material costs which can often be as much as 70% of a part’s cost! Another point to be aware of, is that the YELLOW (risk of splits) is a safety margin before splits are definitely predicted.

It is possible to REMOVE this criterion in which case, the yellow areas would simply turn green (SAFE) but this leaves absolutely no room for production variation.

– See more at: https://stampingsimulation.com/news-article/does_increasing_material_thickness_reduce_the_risk_of_splits/#sthash.u9Acxbfo.dpuf