How to Calculate and Mitigate Springback Effect in Sheet Metal

Contents

Springback is a natural phenomenon in the world of sheet metal fabrication. Companies are constantly finding ways to calculate and mitigate springback effect more effectively. It’s important to understand the springback effect, how it affects your product, and the best ways to calculate and mitigate this effect. Different elastic characteristics of different types of steel will have a profound effect on springback magnitude and direction.

Calculate and Mitigating the Springback Effect in Sheet Metal

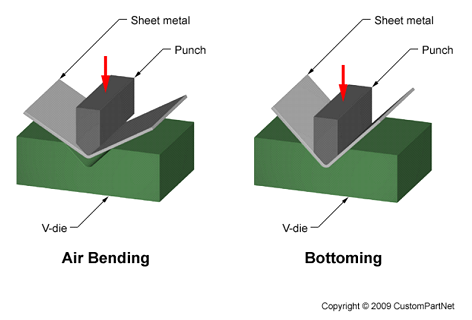

Simple straight line bending will exhibit springback – produce a simple 90-degree bend in any given sheet metal thickness of any grade, and springback will occur. This type of springback problem is easily adjusted for by adding simple “over bend” or compensation. Typically, bending tools take little effort and experience little complications when it comes to solving a straight bend line springback problem. Advanced simulation is not usually required to solve a straight line bending problem.

Solving a straight line springback problem may be as simple as over bending in air.

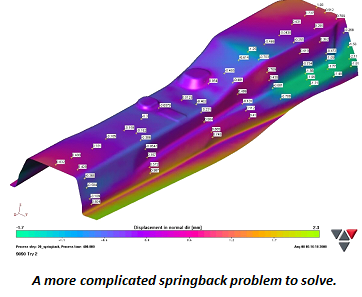

When sheet metal is bent around a corner – or more correctly, “formed” around a corner – the material experiences complicated three-dimensional stresses and strains, and simple “over bending” is no longer a feasible solution to the springback problem. To solve and adjust for springback for anything but a straight line bend, advanced forming simulation technology is needed.

When sheet metal is drawn or stretched into complicated 3D forms and transitions, there is no other method other than advanced simulation technology to efficiently predict and correct for the resulting springback.

AutoForm and Stamping Simulation Solutions

In all of the above cases, as the material strength increases the springback problem becomes more difficult to predict, more difficult to correct, and more difficult to control.

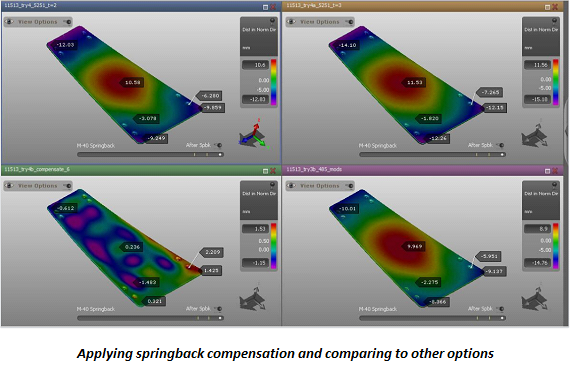

To mimimize cost and mitigate springback problems before they occur, AutoForm and Stamping Simulation technology can accurately predict, correct and control even the most complex springback problem in any sheet metal material, before any tool steel is cut.

To effectively mitigate springback problems before they occur in reality, a complete and successful forming process must be designed and simulated. Needless to say, a forming process that “fails” in simulation (wrinkles or splits) is not ready for springback compensation. Furthermore, a forming process that predicts an “out of control” springback result is not ready for compensation either.

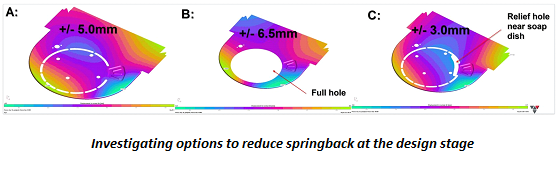

There are multiple approaches to solving springback problems using AutoForm, and compensation is only one method. Often the case may be that the product design does not contain sufficient geometric stiffness to allow springback compensation to work, and therefore additional product stiffness must also be added to the design. Simulation can determine problems at the very earliest stage of product design. Certain design features may also be the cause of a springback problem, and geometric relief may be required to mitigate the problem.

It is nearly always the case that a stretched or deep drawn part, which positively adds strain uniformly all over the part surface, will exhibit reduced springback and improve part dimensional control during production variations. As such, stretching or deep drawing a sheet metal part is often a solution to complicated springback problems in difficult materials.

It is important to note that no simulation software is an automatic decision making robot that magically fixes any springback problem. When combined with experienced tooling knowledge, simulation technology allows engineers to investigate all the possible causes of the springback problem at hand, and then test possible solutions before successfully mitigating the springback problem.

About Stamping Simulation

StampingSimulation provides AutoForm sheet metal forming simulation services, with experienced tooling engineers on hand to discuss your tooling project in every detail, before using simulation as a tool to solve any complex springback problem.

Contact us today to get a free project quote!