The Benefits of Multiple Design Evaluations With Advanced Simulation Technology

Contents

Companies are always working on improving their products and often have to choose between two or more designs quickly. Advanced simulation technology offers a great alternative that can help designers quickly zero-in on the best design, while still assuring the quality of the product. Multiple design alternatives can be assessed with advanced simulations, and decisions can be made early in the design phase, for better or worse.

Advanced Simulation Technology Allows Multiple Design Evaluations

With regard to complex sheet metal product designs, designers often must choose the minimum material thickness and highest strength grade of material to meet today’s legislated requirements for light weight, and subsequent fuel efficiency. These two factors may also be combined with other product requirements, meaning there are often multiple design choices to make and a design study is required before a decision can be made.

Traditionally, design studies may have been conducted using manual calculations, and then spreadsheets as the PC became available. In the last few decades, many CAD programs also embed an array of design study tools which allow basic analysis of design features (such as overall product mass) to be compared with design alternatives.

However, with regards to determining more complex criteria which may be the result of the sheet metal forming process, no standalone CAD system can offer the complex and complete analysis offered by advanced simulation software such as AutoForm.

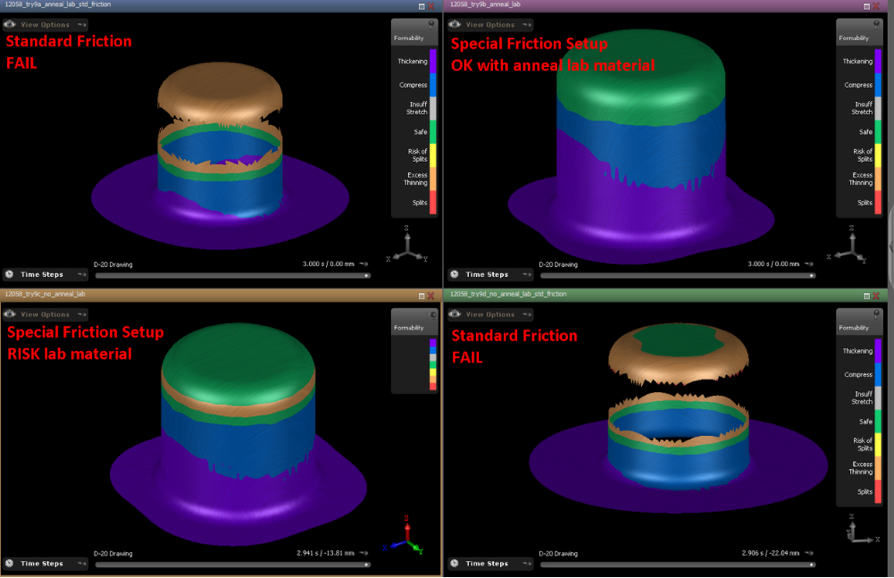

For example, if a sheet metal product is to be optimized for highest strength and least weight, the work hardening effect of the metal forming process must also be considered. No spreadsheet or CAD software will correctly determine the increase in material strength for a complex deep drawn or formed sheet metal product.

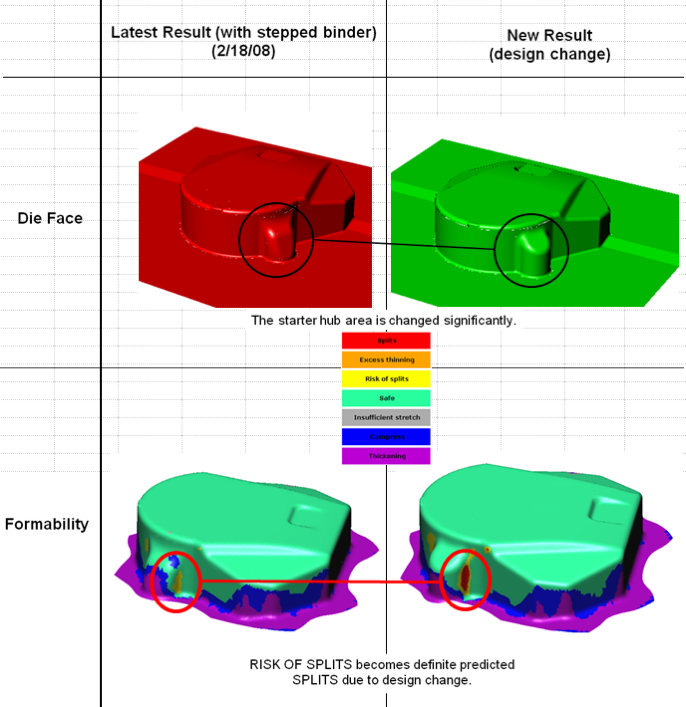

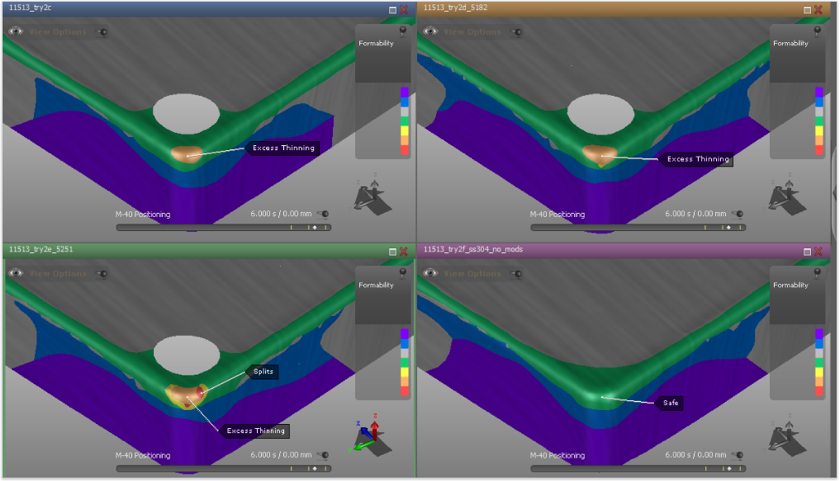

Once the product strength is correctly determined and optimized, it may also be required to understand where the thinnest point on the product lays and whether the overall product strength is compromised or not. Increasing (or decreasing) material thickness may be necessary to completely fulfill all the design requirements, and only multiple advanced simulations can correctly highlight and check for thinning problems.

Naturally, there are many different parameters or design scenarios that can be varied and simulated, to assess almost unlimited design combinations. AutoForm also iteratively runs multiple simulations to statistically determine the best design parameter combination. It may not be enough to run two or three simulations and, with today’s CPU processing power, it’s possible to run tens or hundreds of simulations in a matter of hours or days to assess every combination of design parameter required.

Keep in mind, however, no software on the market today is an automated decision maker on its own. Experienced and trained engineers are always required to understand the results and make the decisions which determine the optimal design. Simulation is the tool which allows that to happen efficiently and cost-effectively.

Learn More…

Would you like to learn more about how simulation software can help your project? Find out how we helped a client with advanced simulation technology here.