AutoForm – Sheet Metal Forming Simulation Software

Not long after our inception around August 2006, StampingSimulation switched to AutoForm sheet metal forming simulation software and has never looked back.

In the last 10 years, AutoForm has firmly taken hold as the market leader in sheet metal forming simulation technology. It’s present in every major Automotive OEM, as well as many other markets that involve the manufacture of sheet metal parts, large and small. For those companies not willing to make their own investment in AutoForm simulation software, StampingSimulation provides on demand AutoForm simulation services to anyone on planet earth.

As a user since the early releases of AutoForm (such as R2, R3.1, etc), I am truly impressed with the continuous development of the unique and innovative AutoForm solver and it’s highly specialized user interface, which is customized to deal with sheet metal forming simulation. AutoForm is truly the only simulation software that is robust and optimized to quickly and accurately simulate sheet metal forming processes, without extreme amounts of training or a PhD in metallurgy.

The earliest versions of AutoForm simulation software had some remarkable functions that made it stand out from any other competitor. It becomes clear to anyone switching to AutoForm from other software, that there are too many advantages to ignore and AutoForm simulation software soon becomes the one and only choice for sheet metal forming simulations.

To be more specific, only AutoForm simulation software can iteratively develop a blank shape through an incremental simulation with many forming/trimming stations. This function was present way back at R2 and was one of the reasons StampingSimulation chose AutoForm simulation software. (AutoForm-Trim plus)

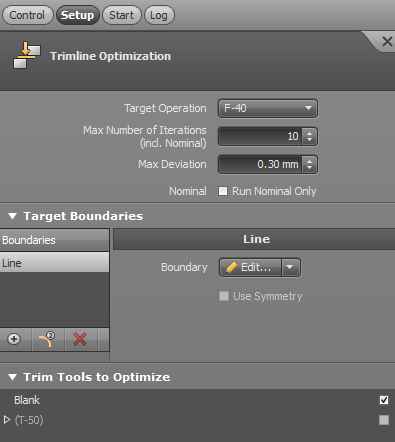

AutoForm-Trim inputs |

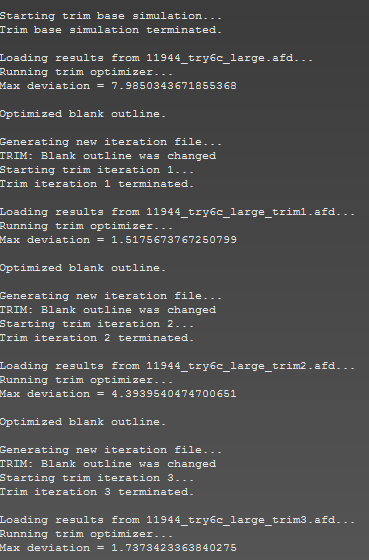

AutoForm-Trim outputs |

The idea that AutoForm simulation software can iteratively and automatically adjust the blank shape (or trimming profiles) requires a demonstration to really appreciate how this works. The process is similar to the shop floor method of laser cutting a 1st trial blank, then forming the part through each station, measuring on a fixture and then adjusting the blank shape (and then repeat over and over).

The same is done in AutoForm simulation software, only in the virtual world. A trim target is set, and Autoform runs incremental simulation through all the process steps, and then measures the error between simulated result and target (aka deviation).

then automatically adjusts the original blank shape, and re-simulates, re-measures, adjusts, and so on until the final target is achieved within a specified tolerance.

This functionality is only one example of AutoForm innovation in the field of sheet metal forming simulation software. Other market leading innovations inside AutoForm simulation software include:

This functionality is only one example of AutoForm innovation in the field of sheet metal forming simulation software. Other market leading innovations inside AutoForm simulation software include:

- Iterative springback compensation. AutoForm-Compensator plus

- Die Designer module which requires almost no external CAD inputs to quickly and completely design working die face geometry. AutoForm-DieDesigner plus

- Draw bead design and physical simulation of beads for drawn parts. AutoForm-ProcessExplorer plus

- Hemming of sheet metal parts, both roller and pressed hem. AutoForm-HemPlanner plus

- Hydroforming simulations, either sheet or tube. AutoForm Hydro

- Simulation of Hot Forming and Quenching Processes. AutoForm-ThermoSolver plus

- Cost estimation of tooling and part. AutoForm-CostEstimator plus

- Prediction of die wear and coating adviser. AutoForm-DieAdviser plus

- Sensitivity studies, optimization and process robustness using statistical analysis over hundreds of simulations. AutoForm-Sigma plus

Looking for an Autoform simulation software company that can provide you with the on-demand services you need? We’re right here to help you! Contact our team today to get a project quote.