Employing Complex Simulations for Industrial Process Improvement

Industrial process improvement is critical in order to make sure all companies are operating at their full potential. Thanks to technological advancements and new policies being put in place, factories need to make the appropriate changes to meet quality, production, and deadline requirements, so they have need to implement process improvement in order to achieve these goals. In this article, we discuss industrial process improvement and how simulation can help improve your factory’s performance for stamped sheet metal parts.

Before non-linear FEA for sheet metal forming became common, the use of 3D CAD was prevalent and perhaps the first process simulations were “moving CAD models” without too much regard for the physics of the real world. Certainly, CAD is not FEA, and process simulations in CAD we not capable of mathematically simulating a sheet metal forming process.

Example “simulation” of a pallet transfer system for stacking parts, using CAD-based tools.

It is fairly common to use such CAD-based tools to define a process, design a process, and then manufacture the system. The normal steps to design such a system are:

- Defining the process

- Designing the process using CAD tools

- Simulating the process using CAD tools

- Improving the process using simulation/design feedback loop

- Manufacture the system

In recent years, the same methodology can be used to design and simulate complex sheet metal forming processes. Advanced non-linear FEA software such as AutoForm make it possible to design, simulate, and improve any sheet metal forming process in the same way CAD software did for production equipment, in the early days of 3D computing.

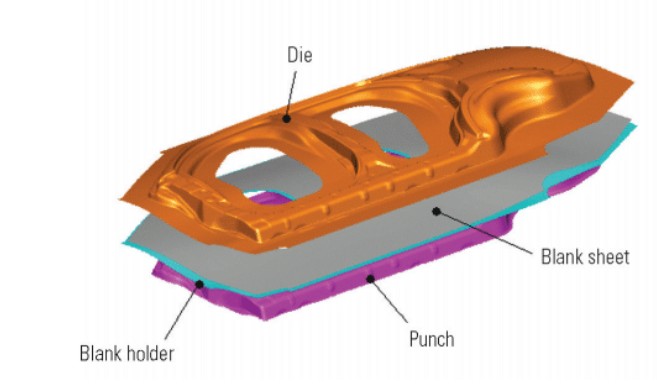

Tooling surfaces used in sheet metal forming simulation

When using simulation to design and improve a sheet metal forming process, we use the simulation tools in the following way:

- Simulate an initial metal forming process as a starting point

- Measure process performance – check for wrinkles, splits, springback, etc…

- Improve the process – design/simulate multiple times to remove defects

- Stabilize the process – vary simulation parameters and check process response

- Finalize the process design and produce 3D models for tooling manufacture

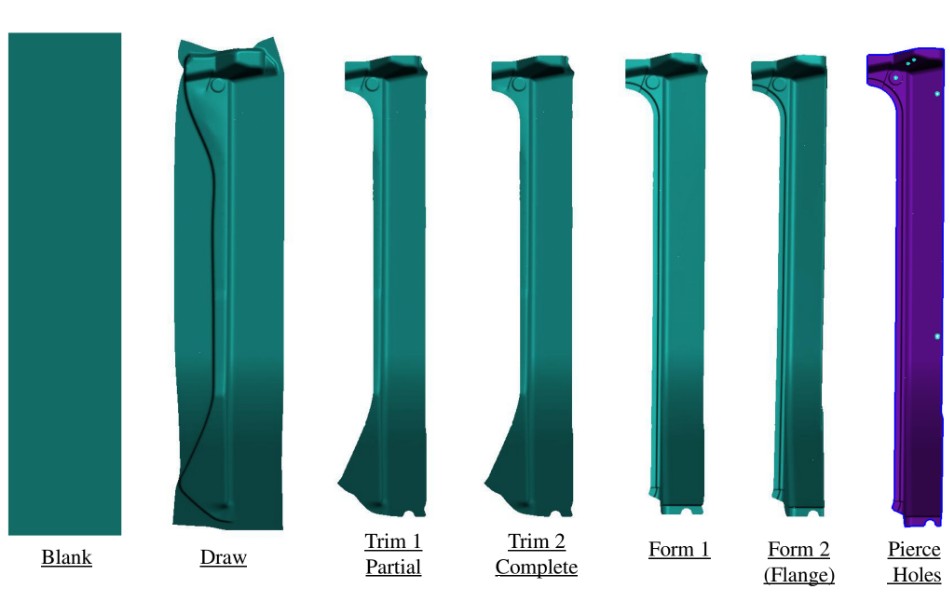

This process was designed, simulated, and improved prior to manufacture of tooling.

StampingSimulation provides sheet metal process design, simulation, and improvement on a consultancy basis using world-class AutoForm software. For examples of real word projects, please visit our Case Studies page.