5 Methods for Creating Your Tube Forming Project

Contents

Tube forming is used in an array of industries, but that doesn’t mean that all tubes are created equal. There are different procedures and materials available, and the perfect match will depend on the usage you will be giving the final product. All manufacturers or entrepreneurs need to make sure they find the best tube forming services for their product. This article has tips on the different types of tube forming methods, and how to find reliable tube forming services and make sure that this stage of your project is a success.

Creating Your Tube Forming Project

Perhaps the most important thing to determine about your tube forming project is whether the tube is a simple bend, a complex series of bends, formed, expanded, hydroformed OR a combination of all methods.

Let’s cover each method and discuss in more detail.

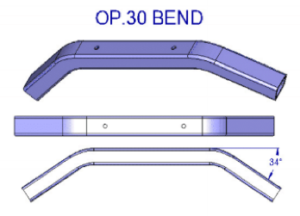

1. Simple Bending. A round hollow tube is bent usually using a mandrel. If no internal support is used during bending, the resulting tube may collapse or disfigure uncontrollably. A simple tube project may include just one bend, and could be done with hand tools.

Simple bending tools with no internal support.

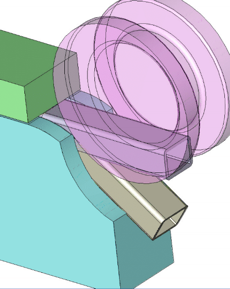

2. Complex Series of Bends. A tube project with multiple bends, at different angles and positions is no longer a simple project. To prevent tube collapse during bending, internal support (such as flexible beads) must be used. For repeatability and volume, a complex tube bending project may use a CNC bending machine, to automate the entire bending process.

Simple bending tools with no internal support.

3. Formed Tube. A tube may be end formed OR otherwise formed from the outside to a desired shape. For example, flattening the end of a round tube. This may be considered to be a simple tube forming project.

Tube end forming. Flattening the end of a round tube.

4. Expanded Tube. A tube maybe be formed (expanded) from the inside, to a desired shape. For example, a round to square transition. This might be done with an inside mandrel OR by mechanical forming tools on CAMs from the inside. A simple end flaring tool would be another example of an expanded tube.

An internally expanded tube. Round to square.

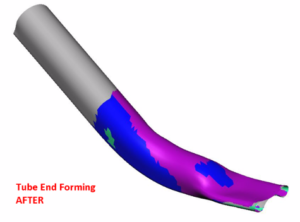

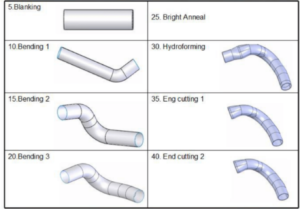

5. Tube Hydroforming. The tube shape is internally expanded using high-pressure hydraulic fluid. An external die surrounds the tube for the pressure to expand against. This is the most complex method of tube forming and requires substantial investment in appropriate equipment. Often, a tube hydroforming project may also include any of the other methods of tube forming PRIOR to the hydroforming step, adding to complexity and cost of manufacture.

A complex tube forming project using multiple forming methods. The process must be determined with simulation to void costly mistakes.

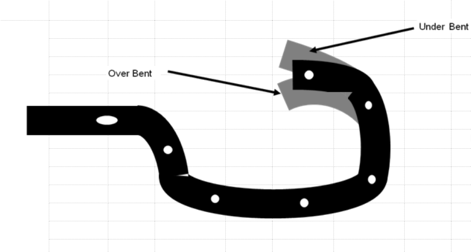

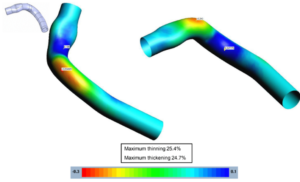

Choosing a supplier or manufacturer for your tube forming project will entirely depend on which forming method your tube design requires. To determine which method your tube project requires to successfully form your tube, full incremental simulation should be used. Simulation allows many iterations in a short space of time to find the correct and most successful forming method for your tube and given material.

Advanced simulation will enable a tool design engineer to design out flaws in the process, such as splits and wrinkles or excessive thinning. Furthermore, a tube manufactured from today’s high strength steels may also struggle to hold dimensional accuracy after forming, and as such, springback compensation is a significant factor for many tube forming projects.

AutoForm Hydro (tube forming) simulation software allows every method of the tube forming process to be simulated in full incremental steps, much the same as sheet metal forming. AutoForm Hydro includes iterative springback compensation for tube forming, to enable engineers and designers to counteract complex springback issues.

Learn More

Interested in learning more about what is possible with advanced simulation software? Take a look at some of our case studies.