3D Printing and How it Affects Your Manufacturing Process

Contents

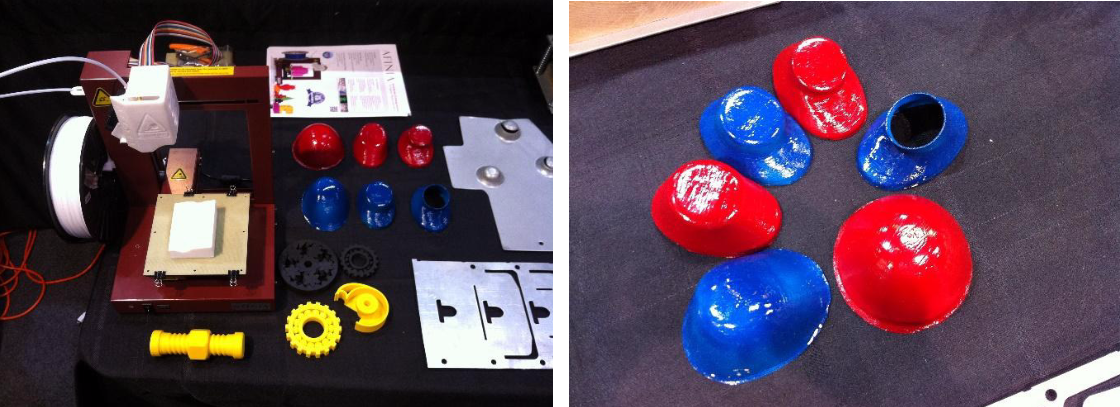

3D printing is one of the hottest topics in manufacturing and tool production, and 3D printers can be used to create parts for an array of industries, from appliances to airplanes and automotive vehicles. Manufacturing prototype parts and hard tooling can be very expensive. 3D printing can help clients create specific pieces on demand, helping them lower their costs.

Although the application of metal 3D printing in the world of sheet metal stamping is still beyond the economic reach of most tooling shops, the use of low cost plastic 3D printers is becoming common for specific and limited items in the sheet metal tooling industry.

How 3D Printing Affects Your Manufacturing Process

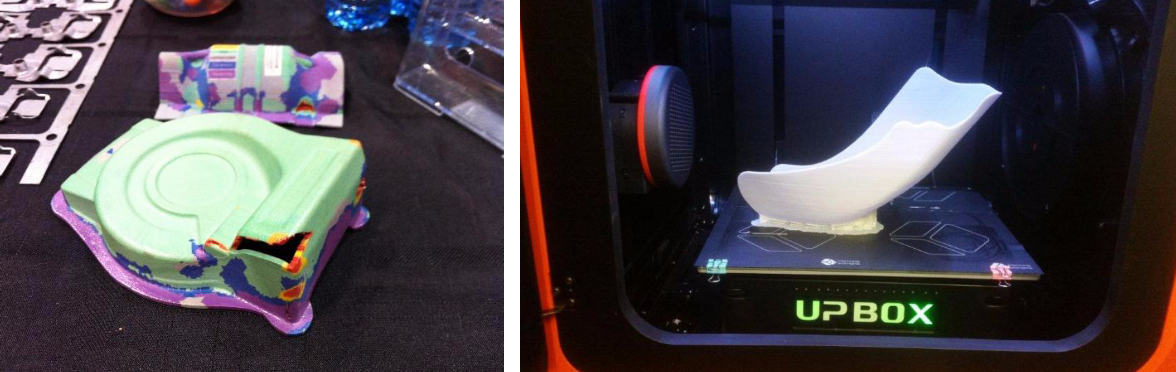

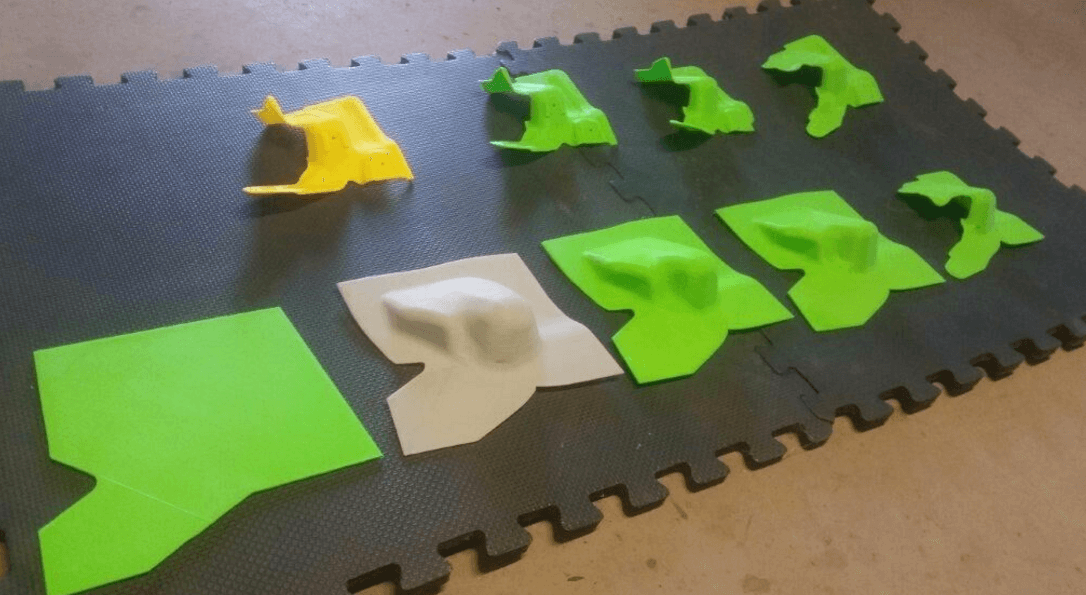

From a simulation point of view, 3D printing can be used to visualize and construct results from the computer screen. This requires full-color 3D printing for best results. However, a low-cost mono-color plastic 3D printer may still have useful output by 3D printing the basic process shapes OR perhaps a full scale developed blank shape for use as a template or physical checking aid.

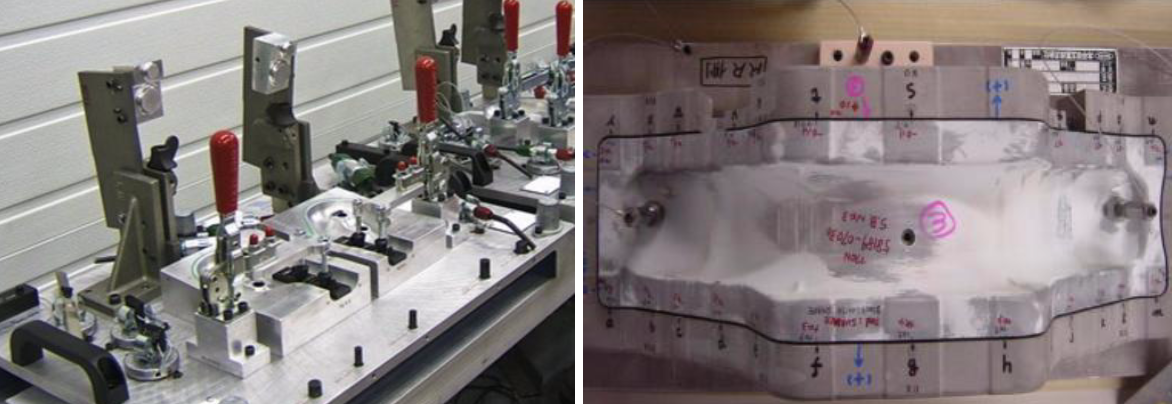

It has also been found to be acceptable to create checking fixtures or gauges using low cost plastic 3D printers, instead of traditional machined gauges which may be slow to manufacture and use expensive materials. In this case, PLA plastic works best (as opposed to ABS plastic) because PLA plastic has a lower melting point and is, therefore, more dimensionally stable and accurate than 3D printed ABS plastic.

Jigs and fixtures are crucial to successful sheet-metal part production, and are used as a manufacturing aid to produce dimensionally accurate sheet metal parts in very high volumes.

Benefits of 3D Printing

The main attraction to 3D printed jigs and fixtures is the fact that creating a 3D printed fixture does not require the expense of a highly skilled CAM operator. Generally, a 3D printed jig is designed in CAD and sent immediately to the 3D printer creating the fixture fast and with automated low-cost labor (i.e., the 3D printer).

Furthermore, a traditional jig or fixture may be heavy and difficult to lift and transport. Naturally, 3D printed plastic is much lighter weight, thereby saving time and energy when transporting the fixture by hand or freight, as is often required.

However, 3D printing is not superior in all cases. There are situations where heat or load requirements of a jig or fixture means 3D printed plastic is not a suitable option. It may also be true on some occasions that a simple shape or part can be more easily CNC machined rather than 3D printed, so one must understand how to use 3D printing appropriately.

Stamping Simulation can offer clients 3D printing services at all levels whether it be mono color, full color, high strength or low strength materials, as well as provide 3D metal printing as an outsourced service. Fill out our online contact form for a free quote.