Understanding Mating Surfaces in Manufacturing

Contents

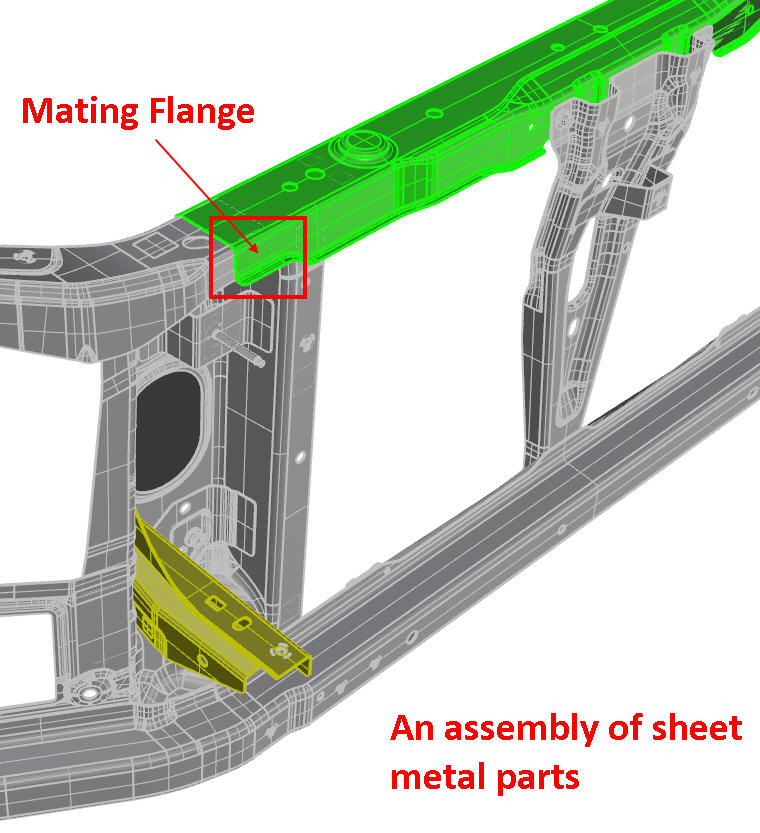

In the world of sheet metal products, and especially an assembly of individual sheet metal parts, mating surfaces or flanges become dimensionally critical.

The definition of “mating” is simply two areas of one or more parts that contact each other. The areas may be flanges, edges, aligning holes (and their surrounding surfaces) or similar features. Usually, the mating areas are joined by a mechanical method such as rivets, spot welding or (in the case of doors, hoods and luggage compartment) hemming.

How are Mating Surfaces Used?

In the case of an automotive shell body there are some 400+ individual sheet metal parts, with hundreds of mating surfaces mostly spot welded together. Given that the target dimensional accuracy of a completed car body is often +/- 2.5mm it is essential that mating flanges on individual parts are dimensionally accurate, usually to +/- 0.5mm. Furthermore, since the final assembly is made up of many sub-assemblies, it is never a simple case of meeting the individual part tolerances, and ending up with a perfectly accurate assembled body.

Each sub-assembly is also assigned a tolerance, and in the case of many automotive companies, a complex system of GD&T is applied across every aspect of every part and every sub-assembly. Furthermore, statistical requirements may also be applied specifying the allowance for variations within the tolerances, making the whole process of mating two parts together very complex, when manufacturing volumes are 100,000s per annum.

However, not all automotive companies are the same. For example, Toyota Motor Corporation threw out the GD&T system. In fact, it never existed within Toyota with respect to the shell body. Instead, the infamous “Toyota Way” evolved and is applied to mating flanges and surfaces very effectively, simplifying an otherwise over complicated system, used by many other OEMs.

The main difference is the recognition of the fact that if the tolerance on an individual mating flange is +/- 0.5mm, for example, and 400 different flanges are all manufactured at -0.4mm (within tolerance), then the error in final assembly of those 400 parts (all within tolerance) could be 160mm! Of course, that is statistically very improbable, but practically, this occurs all too often on a small scale at many OEMs.

The Toyota Way – Mating Surfaces

The Toyota method is simple. Starting with the final assembly (ie: the completed vehicle) specify the required dimensional outcome. Then work backwards, specifying the required accuracy of each major assembly, then sub-assembly, then sub-sub assembly then to each individual sheet metal part, and then finally each individual mating flange or surface. There is no “general tolerance”, instead at each level an expectation arises; for any given mating flange, it must fulfill the dimensional needs of the parent subassembly, and therefore the specified “tolerance” may be away from nominal. For example -0.2/-1.2mm.

This method allows parts to fit inside each other without interference (and without mind boggling terminology!) And provides the ability to “tune” parts away from nominal without being “out of spec”. The Japanese call this “mi-ko-mi” which translated means “expectation”. If it is “expected” that a part or assembly of parts must be on the smaller size to ensure the next assembly will achieve its dimensional requirements, then specifying a “tolerance” that is not based around zero is absolutely allowed.

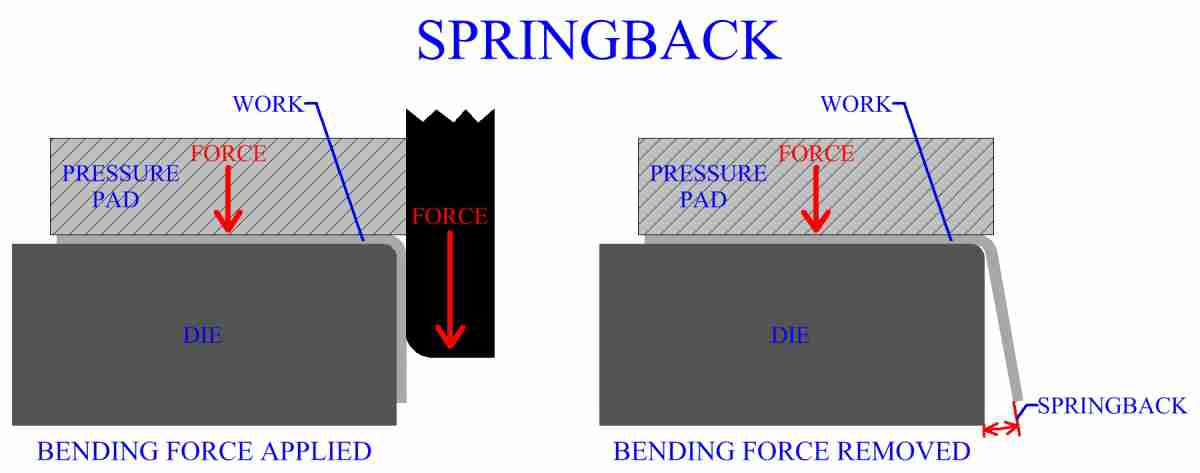

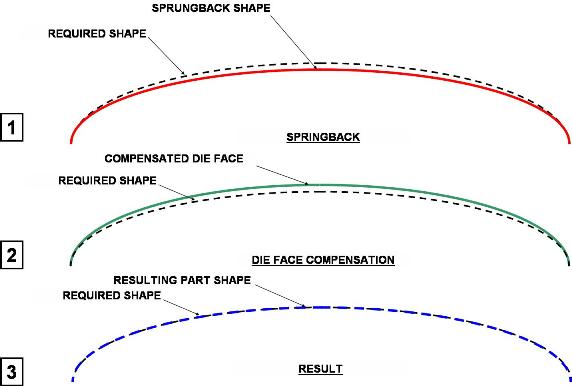

Another example of “mikomi” (expectation) for a mating flange, is with respect to the tooling which creates the flange in a high strength steel. It is “expected” the mating flange will springback and become “out of spec” once formed by the tooling. Therefore, “mikomi” is added to the tooling surfaces to allow for the expected springback, by overbending or over forming the flange such that it springs back to the required position after forming.

The required “expectation” for springback on any mating flange can be calculated by simulation, for even the most complex 3D shapes.

Our team here loves to help engineers solve problems and create better solutions for their manufacturing needs. If you’d like a quote on a current or new sheet metal project, click here.