Choosing the Right Simulation Company

Contents

It is the year 2016 and finding service providers for advanced and complex simulation of sheet metal forming problems is easier than ever. An online search will yield plenty of results. But what should be the key components of a great simulation service?

StampingSimulation at Fabtech 2015 – Chicago

Fixed Cost to Deliver a Tangible Outcome

Some simulation companies will charge an hourly rate while other companies may charge a set fee “per simulation”. Both of these models are an open-ended cost, with no guarantee of an end result!

The StampingSimulation model is different. We quote a fixed cost upfront to deliver a fixed amount of simulation including a solution to your problem. This way, our AutoForm simulation services can be included in your project budget with no fear of an open-ended cost.

Fast and Efficient Service

StampingSimulation utilizes multiple AutoForm licenses for simulation setup and simulation solving. Along with the fact the AutoForm is the most robust and fastest non-linear solver out there, we deliver highly accurate results in your required time frame. We utilize multi-core CPU technology and know how to the use AutoForm exactly how it was intended, efficiently.

Design changes and re-runs take hours, not days or weeks and we pass on results as soon as they are ready. Our engineers are in the USA, UK and Australia covering the full 24-hour timezone cycle…..there is always someone working on your job, even while you sleep.

Simulate First, Model in 3D Last

Designing in CAD is slow. We utilize the powerful die face design tools in AutoForm to quickly assess as many options as needed BEFORE we draw any tooling surfaces in CAD. Only once our client and StampingSimulation are satisfied with the simulation result, will we turn our simulations into solid 3D tooling.

Sounds backward? What we can do in AutoForm in a few hours can take days or weeks in CAD. Simulate first, 3D model last….It’s a proven workflow that puts our clients ahead of their competition.

Industry Experienced, Not Trained Monkeys

All of us at StampingSimulation have years of real world tooling experience, and not just with one type of sheet metal part. We combine real-world knowledge with virtual simulation to get the best outcomes for our clients. We interpret the simulation results and show you exactly what to expect in reality as we work alongside our client’s knowledge to get the desired result. We have seen 100’s of real-world sheet metal stamping tools and have simulated 1000’s more.

Different Levels of Service

Sometimes our client already designed the tooling in 3D CAD. We offer virtual tryouts from your design data (SimulateLite) as well complete process design from scratch (SimulateComplete) — and anything in between. Once we know where your tooling or product design project is at, we offer the right service to give our clients the outcomes they requested. Is your tooling already built and you are experiencing a problem? Our simulation company is able to help after the fact as well — just ask us how!

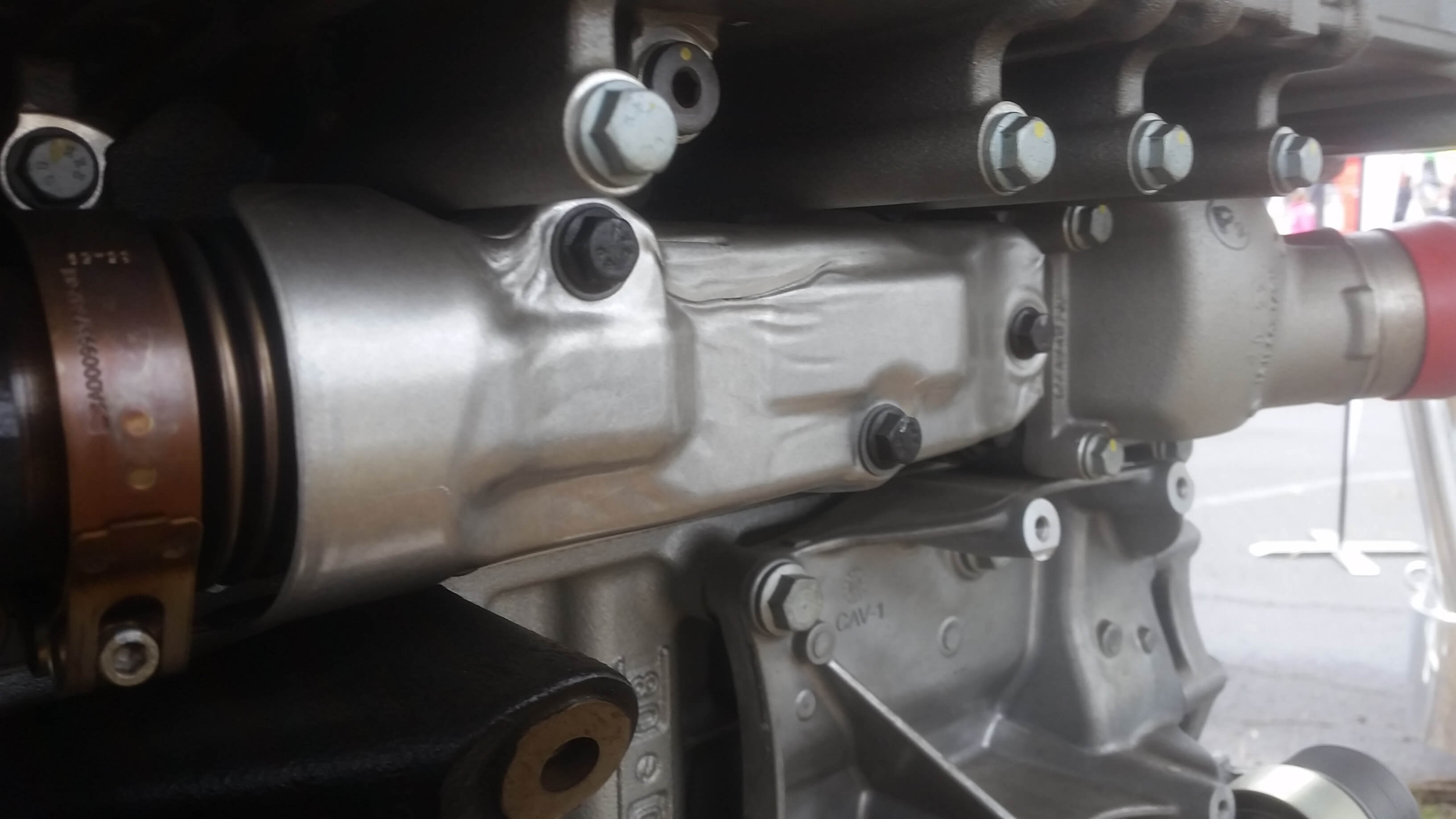

Existing sheet metal forming problems can be solved with simulation.

Final Validation

A simulation is not valid unless the “as built” tool matches the simulation setup. The material used at tryout must match the material information entered into the simulation. The pad/binder pressures need to be set the same as the simulation if the same results are to be expected in reality.

For these reasons, all simulation services end with “final validation” at no extra charge. This means our simulation company service does not stop until your final tooling design, with all the intended pressures, is simulated and validated with lab-tested material data. If our client makes a change that was never simulated, we step up and keep simulating until simulation reflects exactly what is being built.

Work With Our Simulation Company

We’d love to work with you on your next project. Our team is always available to discuss project scope, offer estimates, and answer questions. If you’re interested in working with our team, contact us today to schedule a free project quote and talk to our skilled engineers.