Structural Simulations Services

ANSYS Structural Simulations

StampingSimulation in addition to offering AutoForm Sheet Metal Forming Simulations, also offer ANSYS Structural Simulations. Our ANSYS Simulations are offered as an "on demand" service. Please use any of the contact forms to send us your part data to get a quote.

Better Designs and Shorter Design Cycles

To stay competitive, meet customer demands, and develop innovative and reliable products in ever-shortening design cycles, designers and engineers require simulation tools that offer best-in-class integrated solutions. Our ANSYS structural mechanics solutions offer simulation tools that solve challenging engineering problems and create better products.

Vast Library of Elements and Materials

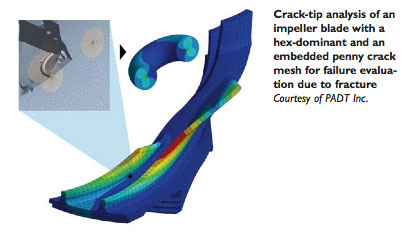

To represent complex real-world geometries, our ANSYS structural mechanics solutions offer:

- Support for a range of elements including beam, shell, solid and solid-shell elements. In addition, pre-tension, joints, gasket, rebars/reinforcements, and other special elements are available.

- A range of linear and nonlinear material models to handle composites, plasticity in metals, hyperelasticity of rubber components, and specialized materials including cast iron, shape memory alloys, porous-elasticity, and cohesive zone models.

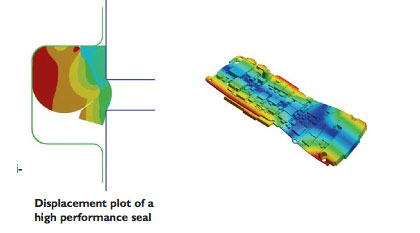

- A robust and complete set of contact capabilities for surface-surface, line-surface, and line-line contact for flexible and rigid bodies. Contact behavior can account for constant or orthotropic friction as well as sliding behavior and is applicable for structural, thermal, and multiphysics contact applications. Fast, automatic contact detection backed by powerful algorithms allows for fast and accurate solving of models involving contacts.

- Simulations also can be extended to a set of comprehensive multiphysics capabilities including thermal-stress, electro-mechanical, structural-acoustics, mass diffusion, and thermal-fluid analysis.

Non-Linear Examples

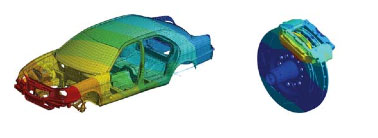

Most product designs and manufacturing processes exhibit complex and non-linear behavior due to sliding contacts with friction between parts and non-linear materials, like metals, solder joints, shape memory alloys, composites, cast iron, plastic, rubber, viscoelastic, non-linear creep, etc.

To predict performance accurately and, subsequently, optimize design, you must employ a simulation solution, like ANSYS, that supports mathematical modeling and solution of highly non-linear behavior. Nonlinear solution technologies from ANSYS offer best-in-class simulation tools for product design and optimization which increase productivity, minimize physical prototyping, and help deliver better, innovative products in less time.

ANSYS non-linear is built upon years of proven, reliable technology and is widely used across such industries as automobile, aerospace, biomedical, electronics, and consumer production.

Dynamics Examples

Most product designs and manufacturing processes exhibit complex dynamic behavior of one or more parts in an assembly. To predict performance accurately and subsequently optimize design, you must employ a simulation solution, like ANSYS, that supports mathematical modeling and solution of highly dynamic behavior. The ANSYS software allows us to model rigid assemblies, flexible components, or any combination of rigid and flexible bodies, using a wide range of methods as shown below.

ANSYS structural mechanics also include a comprehensive set of tools for the simulation of rotating machinery, for all types of geometries including axisymmetric or 3-D solid models.