Stamping Simulation helps Malbern Engineering overcome Splitting Problem

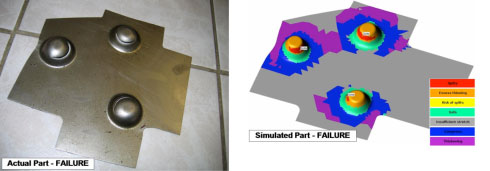

The client had designed and fabricated a tool for a new automotive project. During initial tryout, the process formed the part successfully. HOWEVER, once the tool was set for production, constant SPLITS resulted.

Initially, a simulation of the current process was performed, to determine if the splits were expected. The simulation result shows that indeed, the material is predicted to split. This is due to excessive thinning in the current process.

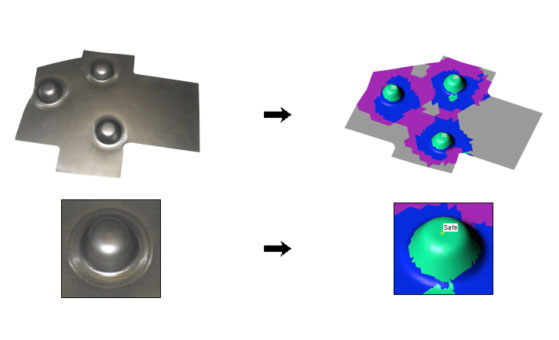

“I decided to modify the 1st stage form tool as per your recommendation and as you can see from the photo’s the proposal was successful. Thank you very much for your input.”

Marco Smargiasso – Technical & Marketing Manager – Malben Engineering

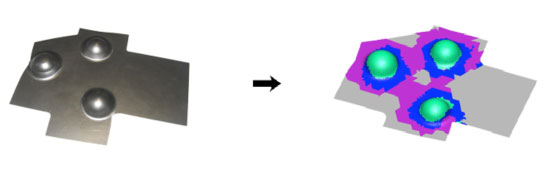

A modification to the pre-form process was proposed, using simulation to engineer and develop the shape.

Based on simulation and engineering development, an optimized pre-form shape was developed. The pre-form shape stretched the material evenly to ensure no excess thinning occurred.

Because of the engineered pre-form shape, the final shape formed successfully, without splits and without excessive thinning. The result is successful and robust.

Using simulation, it was verified that the final shape can be formed without further stretching and without consequential failure. The final form simply moves material, rather than adding more stretch. The simulation shows success and reality agrees.

Related Article: https://stampingsimulation.com/afc-tool-solve-splitting-problem/