An Introductory Guide to Uniaxial Tensile Testing

Contents

StampingSimulation has been speaking for years about the importance of material testing via the uniaxial tensile test. Nothing has changed and for reliable and accurate simulation results a material test is critical. Accurate data in, accurate data out!

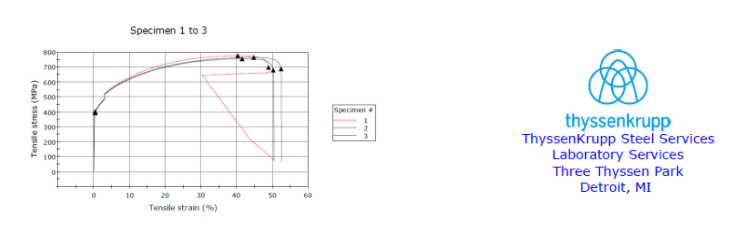

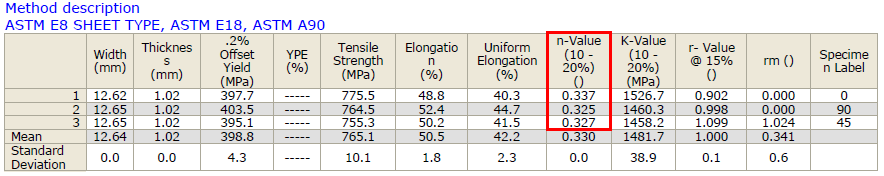

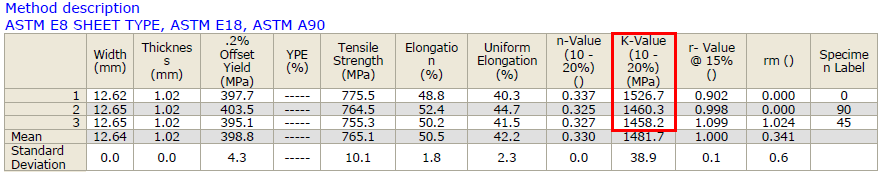

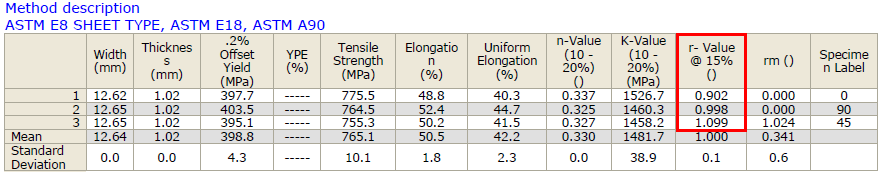

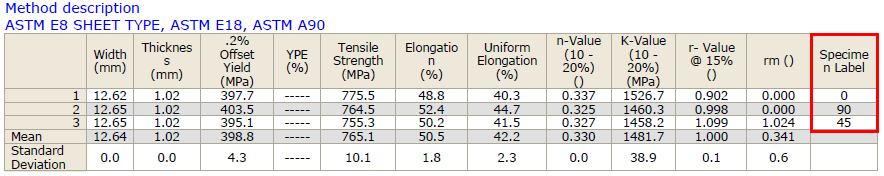

Using the services of ThyssenKrupp labs in Detroit, StampingSimulation offers all customers material testing services as part of every job. The resulting data from ThyssenKrupp labs is a summary report in PDF format, as well as raw data points in CSV format.

Although the raw data points are used as the input to tensile testing simulation, the PDF summary report is very informative and can be “browsed” to get a quick understanding of the material’s formability and other characteristics.

In this article, we explain the common results listed in the PDF summary from the uniaxial tensile test:

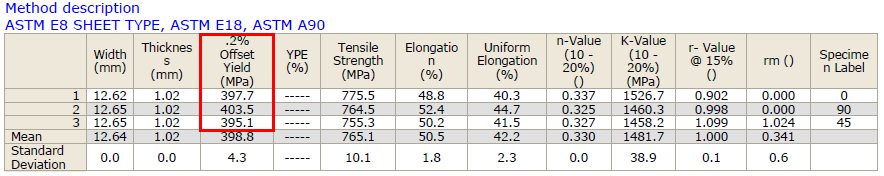

0.2% OFFSET YIELD:

Quite simply this is the material’s Yield Strength. This is the point where the material’s stress-strain behavior is no longer elastic, and begins to become non-linear. This is sometimes called YS.

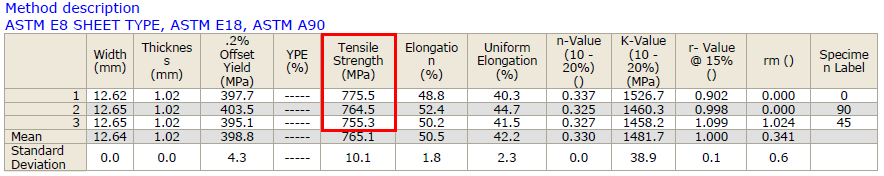

TENSILE STRENGTH:

This is the ultimate strength of the material, sometimes called UTS or TS. This is the point where the material’s strength stops increasing, and failure begins.

When looking at these two values, we can learn or approximate the following:

< 200 MPa. This is a low strength material, perhaps an aluminium. A low strength material may stretch easily but also may fail early due to low strength.

< 200 MPa. This is a low strength material, perhaps an aluminium. A low strength material may stretch easily but also may fail early due to low strength.

> 200 MPa < 400 MPa. This may indicate the material is a regular steel. The strength is considered normal for non-exotic regular steel grades like commercial quality steel or draw-quality steel.

> 400 MPa. High strength material. Maybe dual phase or even stainless steel.

When comparing YS and TS, the difference between when YS and UTS is important. If YS = UTS (or are close together in value), the material will have severe springback and will have very little stretch before failure. A large gap between YS and UTS values may indicate the material can stretch significantly before failure, as is usually the case with austenitic stainless steels where YS = 400MPa and UTS = 750MPa.

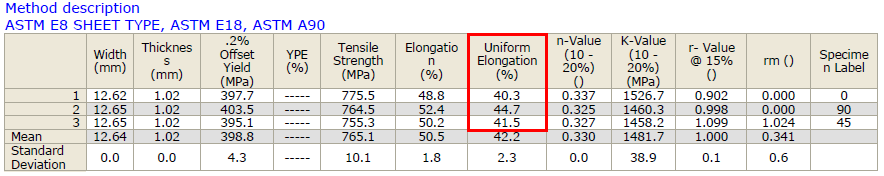

UNIFORM ELONGATION %:

The percentage of stretch before the material fails. <10 % could indicate a poor material for deep forming or drawing. A deep draw quality steel may elongate 25% and stainless steel as much as 45% or higher. Generally, only consider uniform elongation and not “elongation” on the test report as the uniform elongation is a standardized measure.

n VALUE:

Also known as the forming exponent, this number is the exponent in the most basic mathematical model of the non-linear stress-strain curve. Stress is related to strain to the power of “n” which is just a curve fitting formula thru the data points from the test result. Although very basic and not a suitable measure for all material types, low n values <0.10 usually means bad formability, where as draw quality steel might show n~0.23 and stainless steel 0.33 or higher.

K VALUE:

This is a constant in the basic stress-strain formula after curve fitting to data points, and is not particularly relevant for quick interpretation of material results.

r VALUE:

Simply stated, the r values are used to tell simulation software how the material properties change with direction. A cold rolled steel will stretch more in one direction than the other while a hot rolled steel has almost no grain effect, in which case the r values are 1.0 in all directions (or close to 1.0). A deep draw material which stretches better in one direction may show some r values as 1.5 or higher and other directions as 0.9 or less.

SPECIMEN LABEL:

The uniaxial tensile test is performed in three directions to capture material characteristics due to metal grain structure. The rolling direction is usually labeled as 0 degrees. 45 degrees is diagonal to the rolling direction and 90 degrees is across the material grain.

At Stamping Simulation, we are excited to work on tensile testing projects, as well as any other project simulation. If you find that your project would benefit from simulation testing, we’d love to help you. Contact us today to get a free project quote!