Services for all Stages of Your Project

Product Development

- Early formability checks

- Rapid evaluation of multiple designs

- Blank size estimation

Planning & Bidding

- Process planning

- Tonnage calculations

- Material cost studies

Tooling

- 3D process design and simulation

- Precise virtual tryout of 3D tooling

- Accurate blank and trim development

- Integrated springback compensation

- Comprehensive results: formability, thinning, springback, surface quality

Production

- "What if" scenario assessments

- Process improvement studies

- Material change studies

- Cost reduction studies

- Root cause analysis of existing production problems

Your Secret Weapon

Examples of Our Work

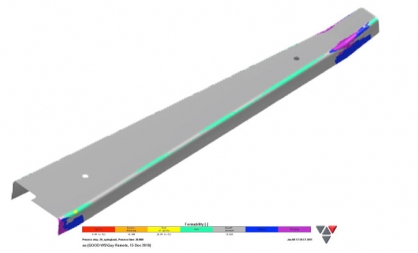

The Challenge:

The Challenge:

- This project's goals were to design a forming process with a maximum of 20% thinning on the plunged holes in the fewest possible operations. The forming process simulations were successful in eliminating forming problems — splits, wrinkles, and other negative outcomes — before the tooling was designed and manufactured.

The Result:

- The dimple was drawn and, through our simulation, we were able to successfully reduce the process to six steps in order to minimize the thinning percentage to the required level. The precut areas were then developed to allow the material to form according to our client’s requirements, giving them the confidence to move the model into the final stages of design and, finally, manufacturing.

Connecticut Corsair is a volunteer organization dedicated to the promotion of education and local businesses in the State of Connecticut. They are also leading an aircraft restoration project aimed at restoring to flight the official State Aircraft of Connecticut — the Chance-Vought F4U Corsair.

Connecticut Corsair is a volunteer organization dedicated to the promotion of education and local businesses in the State of Connecticut. They are also leading an aircraft restoration project aimed at restoring to flight the official State Aircraft of Connecticut — the Chance-Vought F4U Corsair.

The Challenge:

- Recreate the forming process for a section of wing for the Chance-Vought F4U Corsair, a World War II fighter.

The Result:

- After simulations proved the viability of the forming process, Connecticut Corsair successfully formed the wing section on the first attempt.

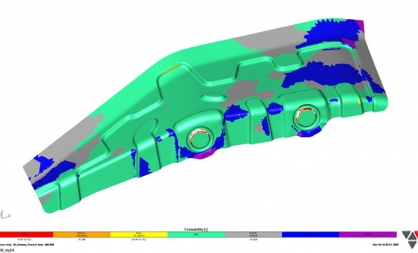

Die Engineering Pty Ltd, a regular StampingSimulation customer, needed to be sure that a part of a complex project could be formed successfully. Earlier prototype parts had been made with unacceptable wrinkles and it was, therefore, the job of our simulation team to determine how to make this part in a way that prevented any wrinkling.

Die Engineering Pty Ltd, a regular StampingSimulation customer, needed to be sure that a part of a complex project could be formed successfully. Earlier prototype parts had been made with unacceptable wrinkles and it was, therefore, the job of our simulation team to determine how to make this part in a way that prevented any wrinkling.

The Challenge:

- Design a forming process that eliminated severe wrinkling or splitting from the part.

The Result:

- Using the simulation results, acceptable parts were made at first tool tryout with no adjustment other than increasing binder pressure to get optimum draw results.

Brands We Work With

Serving Engineers Since 2003

Your problem is our problem. We believe that if we can help you get through your challenges, everyone wins. StampingSimulation has been in the forming simulation business for over a decade. Our experience enables us to quickly and efficiently clear any roadblocks and provide you with sound and effective products and tools, according to your specifications. We are engineers serving engineers and we know your customers can be very demanding. This is why our engineering base works on a “follow the sun” schedule, with engineers across three continents. While you sleep, we work, so that you never have to slow down or lose time on your projects.