5 Things to Know About Tonnage Calculations in Your Sheet Metal Tooling Project

Contents

Sheet metal manufacturing consists of a variety of different processes and is not always easy to understand. Manufacturers are often looking to gain more insights into the steps necessary to create a high-quality, low-cost product – like tonnage calculations. Being able to correctly calculate all tonnages for a sheet metal forming project is fundamental to success, and to keeping the budget’s bottom line in check.

5 Things to Know About Tonnage Calculations

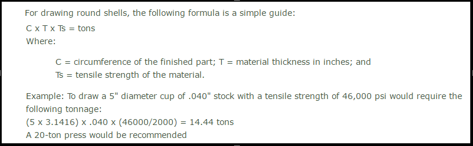

- Simple parts only need simple tonnage calculations: There is no doubt that metal formers with decades of experience and knowledge can calculate tonnages for many simple forming/bending/drawing/cutting/blanking operations with a quick reference to a textbook formula and simple calculation methods. For non-complex sheet metal parts, the traditional method is absolutely correct and there is no reason to make a simple and proven method more complicated.

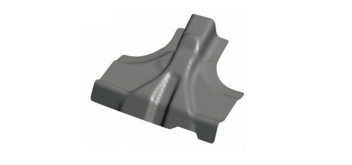

- Complex sheet metal parts need advanced calculation methods: Many sheet metal parts are complex 3D shapes that are too complex to correctly analyze with simple (or even complicated) text book formulas. The basis of many formulas used for such tonnage calculations are uniform and even shapes, with easily calculated surfaces areas, length or volumes. Today’s sheet metal designers don’t focus on simple shapes, but instead design for amazing style, strength, minimal weight and customer satisfaction. This results in many complex 3D form shapes that not only must be formed/drawn in multiple operations, but may also need to be blanked/trimmed/pierced/re-trimmed many times throughout the process.

Complex parts such as this need more than simple calculations.

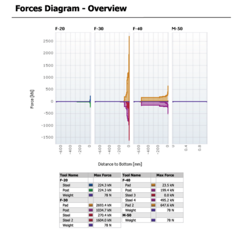

- Advanced simulation technology calculates tonnage for even the most complex sheet metal forming process: Using advanced simulation technology, every force of every step of a sheet metal forming process can be calculated using the Finite Element Method (FEM/FEA). Although FEA is certainly based on calculations, the calculations are of a different nature and consider a finite number of points in a three-dimensional mesh, which represent the blank and tooling at every stage of the sheet metal forming process. This makes the calculation so large and complex that only advanced computing can solve the mathematical equations that determine the correct tonnage for your complex sheet metal forming project.

Forces calculated in simulation are provided for every tooling component in every stage.

- Incorrect binder/pad tonnage will make or break a deep draw tooling project: If your calculation method incorrectly or inadequately estimates binder/pad force for a deep drawing operation, the resulting disaster will cost far more in delays and rework than the cost of an upfront simulation which would have determined the correct tonnage. Worse still, if the available press has inadequate tonnage for the project but was not identified with upfront calculations/simulations, then correcting the error may mean losing the job to a larger press shop.

Insufficient binder tonnage during a draw will allow wrinkles.

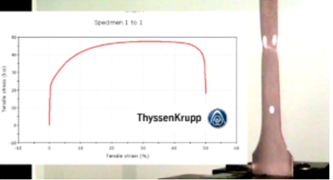

- Know thy steel for correct tonnage calculations: It is absolutely critical that the mechanical properties of the steel to be formed are understood correctly and used in any calculation or simulation that determines tooling tonnages. An incorrect guess of Yield and Tensile strength will lead to incorrect calculation and incorrect simulation results.

The uniaxial tensile test is required to determine accurate material properties.

Get A Quote

StampingSimulation provides advanced simulation services using AutoForm incremental simulation software, including calculation of all tooling forces for any sheet metal forming project. Contact us today for a free project quote for your sheet metal manufacturing needs.

Recommended: https://stampingsimulation.com/fast-track-your-tooling-project/